What is Wind energy?

Wind is a form of solar energy. Winds are caused by the uneven heating of the atmosphere by the sun, the irregularities of the earth's surface, and rotation of the earth. Wind flow patterns are modified by the earth's terrain, bodies of water, and vegetative cover. This wind flow, or motion energy, when "harvested" by modern wind turbines, can be used to generate electricity.

Wind can be used to do work. The kinetic energy of the wind can be changed into other forms of energy, either mechanical energy or electrical energy. When a boat lifts a sail, it is using wind energy to push it through the water. This is one form of work. Farmers have been using wind energy for many years to pump water from wells using windmills like the one on the right.

A wind turbine is a device that converts kinetic energy from the wind into electrical power. A wind turbine used for charging batteries may be referred to as a wind charger. If the wind gets too high, the turbine has a brake that will keep the blades from turning too fast and being damaged.

The earliest known use of wind mill have been from the Ancient East - Windmills were used in Persia (present-day Iran) as early as 200 B.C. The windwheel of Heron of Alexandria marks one of the first known instances of wind powering a machine in history. However, the first known practical windmills were built in Sistan, an Eastern province of Iran, from the 7th century. These "Panemone" were vertical axle windmills, which had long vertical driveshafts with rectangular blades. Made of six to twelve sails covered in reed matting or cloth material, these windmills were used to grind grain or draw up water, and were used in the grist milling and sugarcane industries.

The earliest known use of wind mill have been from the Ancient East - Windmills were used in Persia (present-day Iran) as early as 200 B.C. The windwheel of Heron of Alexandria marks one of the first known instances of wind powering a machine in history. However, the first known practical windmills were built in Sistan, an Eastern province of Iran, from the 7th century. These "Panemone" were vertical axle windmills, which had long vertical driveshafts with rectangular blades. Made of six to twelve sails covered in reed matting or cloth material, these windmills were used to grind grain or draw up water, and were used in the grist milling and sugarcane industries.

DISADVANTAGES OF WIND POWER:

1. The strength of the wind is not constant and it varies from zero to storm force. This means that wind turbines do not produce the same amount of electricity all the time. There will be times when they produce no electricity at all.

2. Large wind turbines as unsightly structures and not pleasant or interesting to look at. Hundreds of wind turbines on the horizon looks bad (but doesn't these overhead telephone cables and high power electric cables look equally bad?).

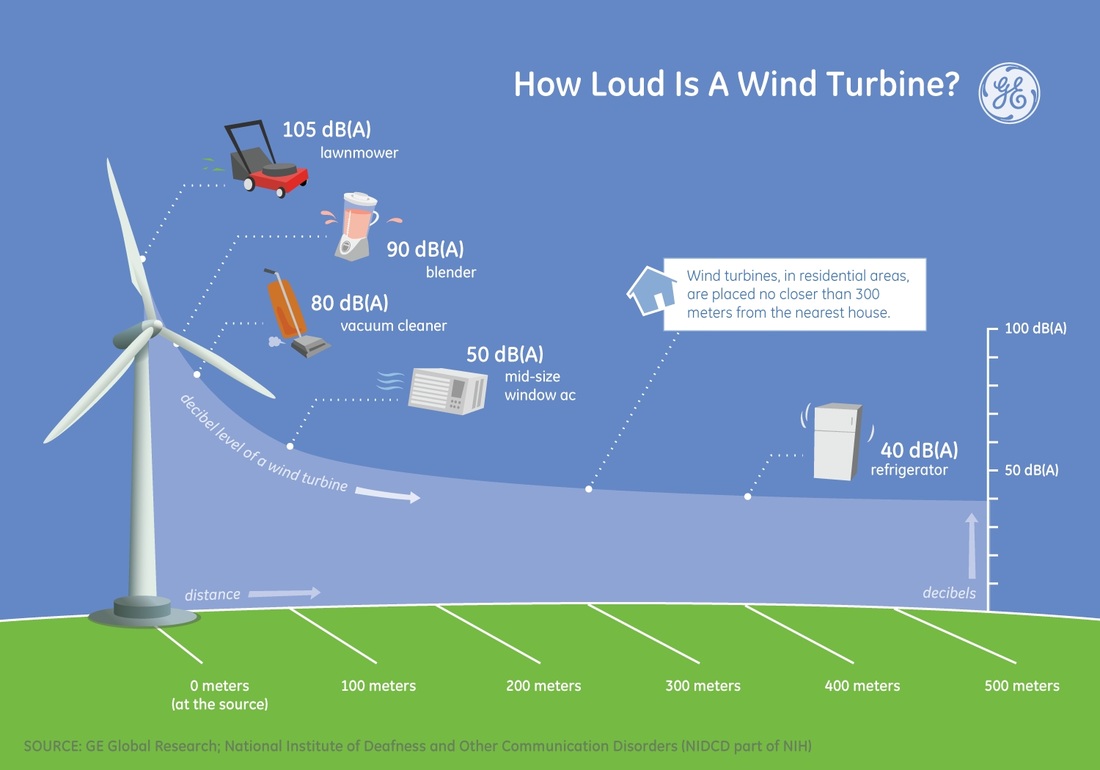

3. Wind turbines are noisy. Each one can generate the same level of noise as a family car travelling at 70 mph.

1. The strength of the wind is not constant and it varies from zero to storm force. This means that wind turbines do not produce the same amount of electricity all the time. There will be times when they produce no electricity at all.

2. Large wind turbines as unsightly structures and not pleasant or interesting to look at. Hundreds of wind turbines on the horizon looks bad (but doesn't these overhead telephone cables and high power electric cables look equally bad?).

3. Wind turbines are noisy. Each one can generate the same level of noise as a family car travelling at 70 mph.

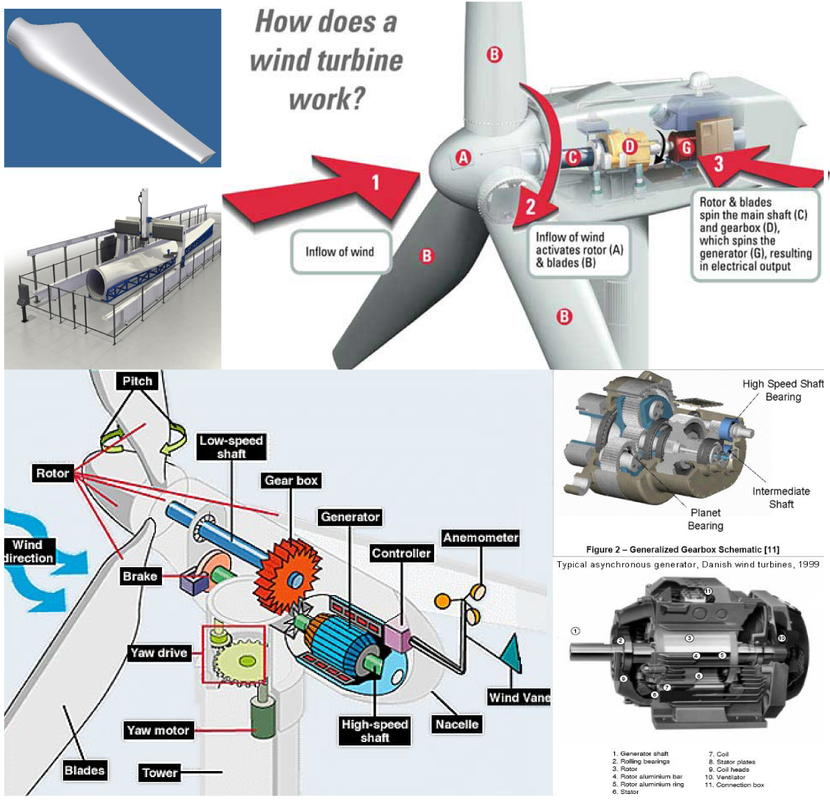

Parts of the Wind Turbine are:

The blades

Designed like airplane wings, modern wind turbine blades use lift to capture the wind's energy. Because of the blade's special shape, the wind creates a pocket of pressure as it passes behind the blade. This pressure pulls the blade, causing the turbine to rotate. This modern blade design captures the wind's energy much more efficiently than old farm windmills, which use drag, the force of the wind pushing against the blades. The blades spin at a slow rate of about 20 revolutions per minute (RPM), although the speed at the blade tip can be over 150 miles per hour.

The nacelle

The nacelle houses a generator and gearbox. The spinning blades are attached to the generator through a series of gears. The gears increase the rotational speed of the blades to the generator speed of over 1,500 RPM. As the generator spins, electricity is produced. Generators can be either variable or fixed speed. Variable speed generators produce electricity at a varying frequency, which must be corrected to 60 cycles per second before it is fed onto the grid. Fixed speed generators don't need to be corrected, but aren't as able to take advantage of fluctuations in wind speed.

The tower

The most common tower design is a white steel cylinder, about 150 to 200 feet tall and 10 feet in diameter. Some turbines use a lattice tower, like the Eiffel Tower. Towers have a ladder running up the inside and a hoist for tools and equipment.

The base

Bases are made of concrete reinforced with steel bars. There are two basic designs. One is a shallow flat disk, about 40 feet in diameter and three feet thick. The other is a deeper cylinder, about 15 feet in diameter and 16 feet deep.

The blades

Designed like airplane wings, modern wind turbine blades use lift to capture the wind's energy. Because of the blade's special shape, the wind creates a pocket of pressure as it passes behind the blade. This pressure pulls the blade, causing the turbine to rotate. This modern blade design captures the wind's energy much more efficiently than old farm windmills, which use drag, the force of the wind pushing against the blades. The blades spin at a slow rate of about 20 revolutions per minute (RPM), although the speed at the blade tip can be over 150 miles per hour.

The nacelle

The nacelle houses a generator and gearbox. The spinning blades are attached to the generator through a series of gears. The gears increase the rotational speed of the blades to the generator speed of over 1,500 RPM. As the generator spins, electricity is produced. Generators can be either variable or fixed speed. Variable speed generators produce electricity at a varying frequency, which must be corrected to 60 cycles per second before it is fed onto the grid. Fixed speed generators don't need to be corrected, but aren't as able to take advantage of fluctuations in wind speed.

The tower

The most common tower design is a white steel cylinder, about 150 to 200 feet tall and 10 feet in diameter. Some turbines use a lattice tower, like the Eiffel Tower. Towers have a ladder running up the inside and a hoist for tools and equipment.

The base

Bases are made of concrete reinforced with steel bars. There are two basic designs. One is a shallow flat disk, about 40 feet in diameter and three feet thick. The other is a deeper cylinder, about 15 feet in diameter and 16 feet deep.

You can use a single smaller wind turbine to power a home or a school. A small turbine makes enough energy for a house. In the picture on the left the children at this Iowa school are playing beneath a wind turbine that makes enough electricity to power their entire school.

In order for a wind turbine to work efficiently, wind speeds usually must be above 12 to 14 miles per hour. Wind has to be this speed to turn the turbines fast enough to generate electricity. The turbines usually produce about 50 to 300 kilowatts of electricity each.

In order for a wind turbine to work efficiently, wind speeds usually must be above 12 to 14 miles per hour. Wind has to be this speed to turn the turbines fast enough to generate electricity. The turbines usually produce about 50 to 300 kilowatts of electricity each.

Since the height of the tower is most of the time around 60 to 60 Meters wouldn't it be great to build the whole structure of cement and put Solar PV cells on the exterior walls? This would create secondary use of the tower and also providing electricity during times of low wind.

Together these three places in California make enough electricity to supply an entire city the size of San Francisco! About 11 percent of the entire world's wind-generated electricity is found in California. Other countries that use a lot of wind energy are Denmark and Germany.

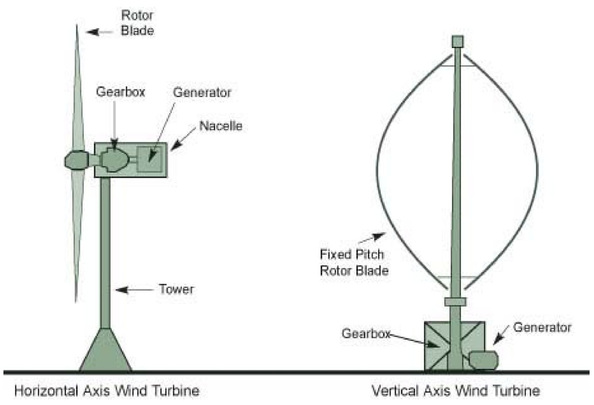

Wind Turbines can be of two types:

1. Horizontal axis design

2. Vertical axis design

1. Horizontal axis design

Horizontal-axis wind turbines (HAWT) have the main rotor shaft and electrical generator at the top of a tower, and must be pointed into the wind. Small turbines are pointed by a simple wind vane, while large turbines generally use a wind sensor coupled with a servo motor. Most have a gearbox, which turns the slow rotation of the blades into a quicker rotation that is more suitable to drive an electrical generator

1. Horizontal axis design

2. Vertical axis design

1. Horizontal axis design

Horizontal-axis wind turbines (HAWT) have the main rotor shaft and electrical generator at the top of a tower, and must be pointed into the wind. Small turbines are pointed by a simple wind vane, while large turbines generally use a wind sensor coupled with a servo motor. Most have a gearbox, which turns the slow rotation of the blades into a quicker rotation that is more suitable to drive an electrical generator

2. Vertical axis design

Vertical-axis wind turbines (or VAWTs) have the main rotor shaft arranged vertically. One advantage of this arrangement is that the turbine does not need to be pointed into the wind to be effective, which is an advantage on a site where the wind direction is highly variable, for example when the turbine is integrated into a building. Also, the generator and gearbox can be placed near the ground, using a direct drive from the rotor assembly to the ground-based gearbox, improving accessibility for maintenance.

Vertical-axis wind turbines (or VAWTs) have the main rotor shaft arranged vertically. One advantage of this arrangement is that the turbine does not need to be pointed into the wind to be effective, which is an advantage on a site where the wind direction is highly variable, for example when the turbine is integrated into a building. Also, the generator and gearbox can be placed near the ground, using a direct drive from the rotor assembly to the ground-based gearbox, improving accessibility for maintenance.

Electricity generated from wind power can be highly variable at several different timescales: hourly, daily, or seasonally. Annual variation also exists, but is not as significant. Because instantaneous electrical generation and consumption must remain in balance to maintain grid stability, this variability can present substantial challenges to incorporating large amounts of wind power into a grid system. Intermittency and the non-dispatchable nature of wind energy production can raise costs for regulation, incremental operating reserve, and (at high penetration levels) could require an increase in the already existing energy demand management, load shedding, storage solutions or system interconnection with HVDC cables.

Fluctuations in load and allowance for failure of large fossil-fuel generating units require reserve capacity that can also compensate for variability of wind generation.

Wind power is however, variable, but during low wind periods it can be replaced by other power sources. Transmission networks presently cope with outages of other generation plants and daily changes in electrical demand, but the variability of intermittent power sources such as wind power, are unlike those of conventional power generation plants which, when scheduled to be operating, may be able to deliver their nameplate capacity around 95% of the time.

Presently, grid systems with large wind penetration require a small increase in the frequency of usage of natural gas spinning reserve power plants to prevent a loss of electricity in the event that conditions are not favorable for power production from the wind.

Fluctuations in load and allowance for failure of large fossil-fuel generating units require reserve capacity that can also compensate for variability of wind generation.

Wind power is however, variable, but during low wind periods it can be replaced by other power sources. Transmission networks presently cope with outages of other generation plants and daily changes in electrical demand, but the variability of intermittent power sources such as wind power, are unlike those of conventional power generation plants which, when scheduled to be operating, may be able to deliver their nameplate capacity around 95% of the time.

Presently, grid systems with large wind penetration require a small increase in the frequency of usage of natural gas spinning reserve power plants to prevent a loss of electricity in the event that conditions are not favorable for power production from the wind.

How much do wind turbines cost?

Wind turbines come in many shapes and sizes, but here is a general guideline on how much they cost:

Total costs for installing a commercial-scale wind turbine will vary significantly depending on the number of turbines ordered, cost of financing, when the turbine purchase agreement was executed, construction contracts, the location of the project, and other factors. Cost components for wind projects include things other than the turbines, such as wind resource assessment and site analysis expenses; construction expenses; permitting and interconnection studies; utility system upgrades, transformers, protection and metering equipment; insurance; operations, warranty, maintenance, and repair; legal and consultation fees. Other factors that will impact your project economics include taxes and incentives.

Wind turbines come in many shapes and sizes, but here is a general guideline on how much they cost:

Total costs for installing a commercial-scale wind turbine will vary significantly depending on the number of turbines ordered, cost of financing, when the turbine purchase agreement was executed, construction contracts, the location of the project, and other factors. Cost components for wind projects include things other than the turbines, such as wind resource assessment and site analysis expenses; construction expenses; permitting and interconnection studies; utility system upgrades, transformers, protection and metering equipment; insurance; operations, warranty, maintenance, and repair; legal and consultation fees. Other factors that will impact your project economics include taxes and incentives.

What is startling is that China has invested 16 times more (16,088 vs 1,084) than US and its capacity has almost doubled that of US yet China gets dubbed as the world's most polluting country...strange! Even Germany, UK, India and Canada has invested more last year than the US. Either the US economy has stagnated a lot or nobody in US cares anymore!

The costs for a utility scale wind turbine in 2012 range from about $1.3 million to $2.2 million per MW of nameplate capacity installed. This cost has come down dramatically from what it was just a few years ago.

Most of the commercial-scale turbines installed today are 2 MW in size and cost roughly $3-$4 million installed. Wind turbines have significant economies of scale. Smaller farm or residential scale turbines cost less overall, but are more expensive per kilowatt of energy producing capacity. Wind turbines under 100 kilowatts cost roughly $3,000 to $8,000 per kilowatt of capacity. A 10 kilowatt machine (the size needed to power a large home) might have an installed cost of $50,000-$80,000 (or more) depending on the tower type, height, and the cost of installation. Oftentimes there are tax and other incentives that can dramatically reduce the cost of a wind project.

Most of the commercial-scale turbines installed today are 2 MW in size and cost roughly $3-$4 million installed. Wind turbines have significant economies of scale. Smaller farm or residential scale turbines cost less overall, but are more expensive per kilowatt of energy producing capacity. Wind turbines under 100 kilowatts cost roughly $3,000 to $8,000 per kilowatt of capacity. A 10 kilowatt machine (the size needed to power a large home) might have an installed cost of $50,000-$80,000 (or more) depending on the tower type, height, and the cost of installation. Oftentimes there are tax and other incentives that can dramatically reduce the cost of a wind project.

Whats inside the Wind Turbine? Check out the below video.

Wind Tamer Technology claims to be the most efficient Wind Energy system:

During heavy winds these turbines usually shut down at about 25 m/s or 55 mph, this is the maximum operational limit The time span in the below video is about 2 hours while the wind speed went up from about 18 m/s to 30 m/s. When the wind was gusting up to 30 m/s the rotor blades were pitched out of the wind. (Keep an eye on the angle of the blades at the start of the video and then towards the end of the video):

Researchers have proved through simulations that Wind Mills can slow down and even disperse Storms as powerful as Katrina. See the below video:

Nikola Tesla's favorite invention: His Turbine that can convert 98% efficiency!

Testing the Turbine theory

RESIDENTIAL USE_________

Frequently Asked Questions on Wind Turbine:

What size turbine is needed to power an entire home?

On average, a typical home would require a small turbine with a 5-kilowatt generating capacity to meet all its electricity needs. A machine of this size has a diameter of approximately 18 feet. The exact size needed to power a home, however, can range from 2 kW to 10 kW (12-25 ft. diameter) based on a home’s energy use, average wind speeds, and the turbine’s height above ground (which affects its productivity).

How tall are they?

The average height of a small wind turbine (of any capacity) is about 80ft. (about twice the height of a neighborhood telephone pole), with a range of 30-140 ft. Generator size and tower height are not generally related; a 5-kW turbine could be on a tower anywhere from 30-140 ft. in height, for example. However, for good performance, experts recommend that small turbines be installed at a height of at least 30 feet above nearby obstructions such as trees.

What is the average payback period?

The length of the payback period depends on the turbine, the quality of wind at the installation site, prevailing electricity rates, and available financing and incentives. Depending on these and other factors, the time it takes to fully recover the cost of a small wind turbine is 6 to 30 years.

What happens when the wind does not blow?

For grid-connected systems,the user will not notice a difference when the wind is not blowing. The utility provides electricity when the wind does not blow, and any extra electricity the turbine generates is sent back to the utility system to be used by a neighbor. Off-grid turbines store power in batteries for on-demand use and are often complemented by solar electric panels to provide more consistent generation.

Do I need to take wind measurements?

Taking detailed measurements to gauge your wind resource is often unnecessary. Experienced installers/dealers or manufacturers can determine whether your property is suitable for a system by inspecting the surrounding area.

How much land and wind are required? Will my town let me install a turbine?

Installers recommend sites with average wind speeds of at least 12 mph, but specific land requirements vary from place to place. Zoning codes sometimes impose a minimum requirement on lot size or on the distance a turbine maybe placed from a property line, and may vary depending on the height of the proposed turbine. Also, it is essential to have a site with unobstructed access to winds, which most often requires higher towers, larger land lots, and non-urban locations. Currently, less than 1 percent of all small wind turbines are used in urban applications partly due to zoning restrictions, but mostly because wind quality is much poorer in densely built environments. Contact your turbine factory dealer for help navigating the permitting process.

How does the rated capacity of a small wind system compare to its actual performance?

Rated capacity indicates the electric power (kilowatts) a turbine will generate at a given wind speed, so the answer depends on wind speed and the turbine. A more accurate indicator of energy production, however, is swept area. A 5-kW turbine (average residential size, 18ft. rotor diameter) produces around 8,000 kWh per year in 12-mph average winds, which is about 100 percent of what an average U.S. home requires. At the larger end of the spectrum, a 100-kW turbine (60ft. diameter) in these conditions will generate around 200,000 kWh per year.

Are batteries or other storage needed?

There are two types of systems: those connected to the electricity grid (“on-grid”) and those used off-grid (for battery charging) or backup power. Many systems sold today are off-grid, but demand is rising for on-grid systems which essentially use the grid as a "battery": when the wind blows, the owner uses electricity from the turbine; when winds are low and consumption is high, the owner uses electricity from the grid. The smallest wind turbines are often used in conjunction with solar photovoltaic technology.

How are small wind systems maintained?

Routine inspections should be performed once a year of a turbine’s 20+-year life span. A professional installer or trained technician (usually the manufacturer or dealer that sold the turbine) maintains the turbine and tower through physical inspections, though some turbines can be monitored remotely from a home computer.