By Team Ather

We at Ather energy have an update, regarding the development work of 'S340' - The next generation electric scooter.

'S340' is the much anticipated electric scooter that will raise the bar to a very high level as compared to current generation e-bikes being sold in India.

We have an update about the in-house Battery Management System(BMS) that is being developed and rigorous testing of the 'S340' at ARAI (Automotive Research Association of India), Pune. We also have moved to a new office!

'S340' is the much anticipated electric scooter that will raise the bar to a very high level as compared to current generation e-bikes being sold in India.

We have an update about the in-house Battery Management System(BMS) that is being developed and rigorous testing of the 'S340' at ARAI (Automotive Research Association of India), Pune. We also have moved to a new office!

The Ather BMS

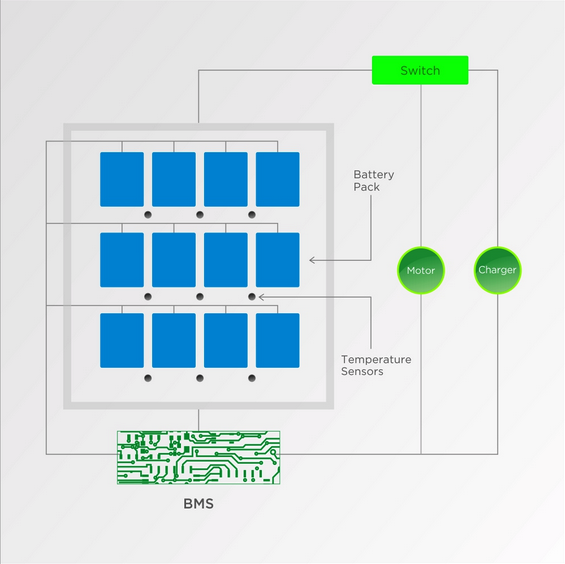

A centralized BMS is primarily an electronic system that is connected to all the cells in a battery pack and constantly measures their voltage and current. Additionally multiple temperature sensors placed across the pack constantly provide the BMS with temperatures at different sections of the battery pack. Hence at any point of time the BMS monitors:

A centralized BMS is primarily an electronic system that is connected to all the cells in a battery pack and constantly measures their voltage and current. Additionally multiple temperature sensors placed across the pack constantly provide the BMS with temperatures at different sections of the battery pack. Hence at any point of time the BMS monitors:

- Individual cell voltage, total voltage, minimum & maximum voltage

- Temperatures from each sensor, in each section of the pack and overall battery pack heating

- State of charge of the cells and the battery pack

Having an in-house designed fast charger and battery pack itself adds to the complexity in integrating them with a regular BMS. Most off-the shelf BMS have limited thermal interface and are restricted to SMBus communication. With a standard BMS it also becomes nearly impossible to work around space constraints.

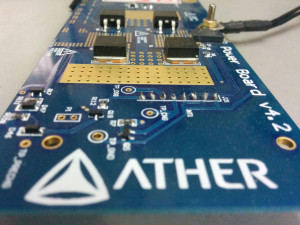

Designing an in-house BMS not only negates these disadvantages but also offers more options. Our BMS design incorporates multiple thermal sensors enables us to get extensive heat data inside the BMS. The bigger advantage is that we get to identify & integrate individual components which are most appropriate for our specific requirements. This makes features like Over the Air updates possible and comes built-in with the first version itself. The board also includes a separate controller for data analysis and sharing them with dashboard & cloud.

Though one of the biggest challenge, integrating our own BMS helps in working around space constraints. More importantly, we will be using a far more advanced BMS at one-tenth of the cost of the ones available in the market. We already have designed and built multiple functional prototypes which are currently being tested under different conditions. Apart from minor iterations which may be suggested from these test results we have an advanced and smart Battery Management System ready to tame all the brawn of the Ather S340.

Designing an in-house BMS not only negates these disadvantages but also offers more options. Our BMS design incorporates multiple thermal sensors enables us to get extensive heat data inside the BMS. The bigger advantage is that we get to identify & integrate individual components which are most appropriate for our specific requirements. This makes features like Over the Air updates possible and comes built-in with the first version itself. The board also includes a separate controller for data analysis and sharing them with dashboard & cloud.

Though one of the biggest challenge, integrating our own BMS helps in working around space constraints. More importantly, we will be using a far more advanced BMS at one-tenth of the cost of the ones available in the market. We already have designed and built multiple functional prototypes which are currently being tested under different conditions. Apart from minor iterations which may be suggested from these test results we have an advanced and smart Battery Management System ready to tame all the brawn of the Ather S340.

Testing to its limits

The S340 is being rigorously tested on various parameters. One of the prototypes is currently at ARAI (Automotive Research Association of India), Pune, where it will be put through fatigue testing. Mounted on a special rig, the vehicle structure will be pushed to its limits over a 50 hour intense test - equivalent to 1,00,000 kms of ride on regular roads. This exercise will provide us with sufficient data to analyze & predict fatigue, calculate vehicle life more accurately and also simulate the structural behaviour in other scenarios.

Meanwhile a second prototype is being tested with multiple shock absorber configurations. With enough experience of riding on Indian roads, we want to ensure that the S340 offers exceptional ride comfort. This relentless pursuit has already got us a few casualities - a bruised & battered prototype and 2 test engineers with not-so-serious injuries.

The S340 is being rigorously tested on various parameters. One of the prototypes is currently at ARAI (Automotive Research Association of India), Pune, where it will be put through fatigue testing. Mounted on a special rig, the vehicle structure will be pushed to its limits over a 50 hour intense test - equivalent to 1,00,000 kms of ride on regular roads. This exercise will provide us with sufficient data to analyze & predict fatigue, calculate vehicle life more accurately and also simulate the structural behaviour in other scenarios.

Meanwhile a second prototype is being tested with multiple shock absorber configurations. With enough experience of riding on Indian roads, we want to ensure that the S340 offers exceptional ride comfort. This relentless pursuit has already got us a few casualities - a bruised & battered prototype and 2 test engineers with not-so-serious injuries.

Ather gets a new address

After a two month long exhausting wait, we have finally moved to our new office space in Victoria Layout, Bangalore. Our one and only mission is to design & build smart vehicles. But over the last couple of weeks we did learn a few additional lessons on converting a bare structure to a habitable workspace :) Unlike a regular workspace, we also had to accommodate labs, prototyping area, a clay modelling studio and workshops, all under one single roof. Though this is not our area of expertise, we will be glad to share the few lessons we learnt in our next blog.

After a two month long exhausting wait, we have finally moved to our new office space in Victoria Layout, Bangalore. Our one and only mission is to design & build smart vehicles. But over the last couple of weeks we did learn a few additional lessons on converting a bare structure to a habitable workspace :) Unlike a regular workspace, we also had to accommodate labs, prototyping area, a clay modelling studio and workshops, all under one single roof. Though this is not our area of expertise, we will be glad to share the few lessons we learnt in our next blog.

We are exploring an option to give you a live tour of the new office. More updates on that soon!

Contact

Ather Energy

[email protected]

[email protected]

Mobile: +91 99520 93 37

Website - http://atherenergy.com/

Contact

Ather Energy

[email protected]

[email protected]

Mobile: +91 99520 93 37

Website - http://atherenergy.com/