In this episode of EV guru we show were Indian EV Industry is in terms of localisation and we showcase how many industries are dependent on China.

Ultimately we speak about taking the pragmatic approach for our Indian EV Industry.

In this episode of EV Guru we will talk about

- Where the Indian EV Industry is, in terms of localization.

- What are components of an EV and which components have a dependency on China and which components can be made in India. You will be surprised, most components in Electric Vehicles CAN be made in India today.

- We will talk about Chinese companies investing in India and selling vehicles.

- We will also speak about how multiple industries are dependent on China much more than the Indian EV industry.

Let’s talk about electric cars

- Mahindra Electric has their very successful eVerito electric car and this car is majorly engineered in India with the help of the Reva Electric Car company who they purchased in 2010. We know for a fact that they make the Lithium Iron Phosphate battery packs in house and many of the electronic components like motor controller, onboard charger are made by Indian companies.

The upcoming eKUV is going to be launched soon and we are sure this will be a highly localized product. - Tata Motors unveiled their electric car vision with multiple Tata companies like Tata Power, Tata AutoComponents, Tata Chemicals and more Tata companies coming together to support the EV Ecosystem.

- Hyundai Kona and MG Motors have launched electric cars in limited numbers. They are getting CKD kits from Korea and China respectively. We feel their main focus is to sell pollution cars in India and they have launched Electric Cars for branding only.

Let’s talk about electric buses. The 3 biggest players here are

- Olectra Greentech Ltd

They are a partnership with an Indian company and world's biggest Chinese electric bus manufacturer BYD - PMI Electro Mobility Solutions

They are a partnership with an Indian company and another large Chinese electric bus manufacturer Foton - Our very own Tata Motors

Who recently bagged the largest electric bus order of 300 buses Ahmedabad Janmarg Limited.

The subsidy is available only if manufacturers localize certain key components.

Let’s talk about the biggest segment - the e-Rickshaw segments

- There is a large unorganised sector with multiple manufacturers selling eRickshaws.

- We got to know that many of these companies who sell e-Rickshaws get the entire body from China. The body of the e-Rickshaw includes Shockers, wheels, chassis, suspension etc. Generally these Chinese bodies have smaller wheelbase, lower ground clearance - not made for Indian roads.

- Then we have the electrical components like lights, wire harness, controllers etc. These also are from China.

- Then we have Motor which is 100% from China

- The lead acid batteries used are 100% Made in India.

- We have large players in the eRickshaw business like

- Kinetic Green, Exide, Mahindra, Thukral

- These large players have service centers pan India. They import only motor, rest everything is Made in India. These players sell heavily localized eRickshaws.

The electric auto market is still a small one.

- We already have a Mahindra Treo lithium ion based eAuto that is doing well. We know that the Mahindra electric Treo team has worked very hard to make this a majorly Made in India product as most components are made in India.

- We also know Bajaj are launching an e-Auto in few months which is also majorly made in India product.

Lets talk about the charging stations market

- Regarding charging stations, we spoke to some industry insiders and they said that AC charging stations are totally possible to make in India as most components are available in India.

- Regarding DC fast chargers there are some components which are imported.

- Some big players in India are Delta which is a Taiwanese company, Siemens and EO are importing chargers from Europe and Indian companies like Masstech, Exicom, OnePlug, BrightBlu are making Indian charging stations.

Let’s talk about the market which has largest potential. Electric scooters.

- Back in 2015-16, most electric scooter companies were 100% importing CKD kits usually from China. But that situation has improved a lot now. With stricter regulation and FAME 2 policy changes many of these companies have been forced to localise their operations.

- Big electric scooter names like Hero Electric, Okinawa, Ampere have started localizing and around 50%-60% of their operations are localized especially in their FAME 2 compliant scooters.

- Ather Energy, Tork Motors, Ultraviolet are few startups who make the majority of their own components and have vertical integration in the manufacturing processes.

- Progressive smaller scooter startups like PureEV, NDS Eco, Batt:Re are moving towards localizing 80% upto localization by the end of 2020.

Then we have many smaller companies - regional players who are still selling CKDs from China as they only sell low speed scooters there is no mandate for these companies to localize.

Our wish for FAME 3 would be to target low speed scooters which will encourage these companies to localize more.

But overall we at PluginIndia are happy with the way the electric scooter industry is working towards localization. There is more work to be done but we are confident of seeing a 90% Made In India electric scooter by this year end.

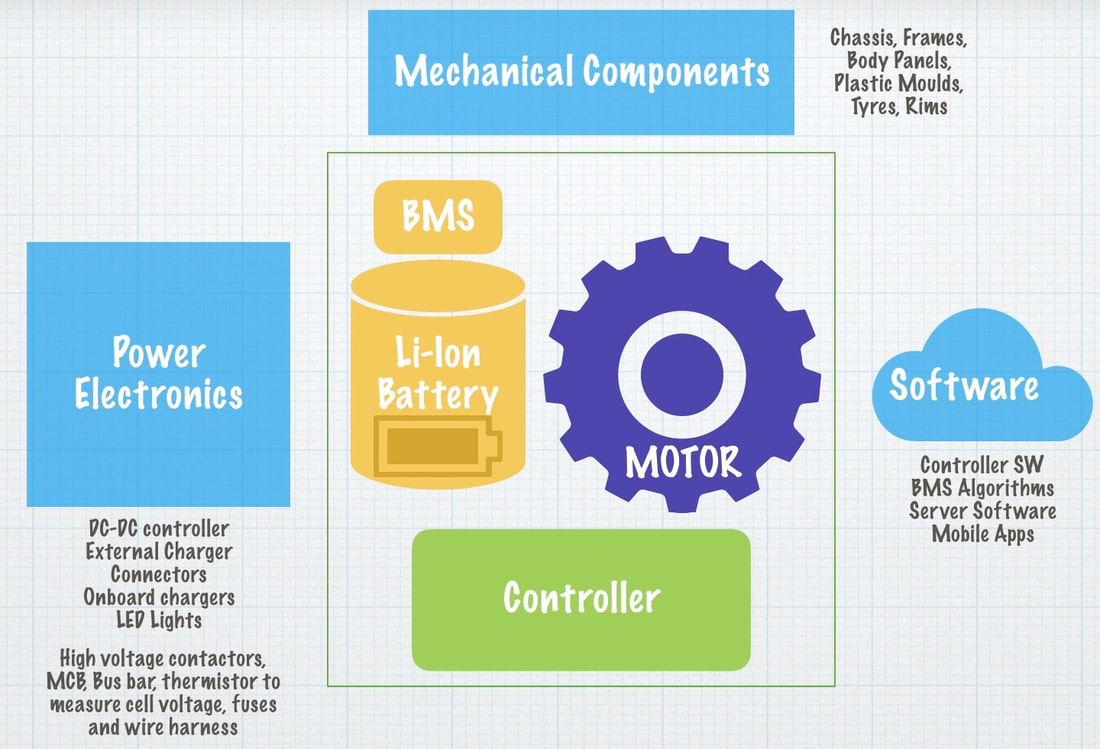

Every component of an EV can be Made In India, although there are some exceptions. Let's take an electric scooter for example.

The below figure will give you an idea about the components needed for an electric scooter.

- Battery Packs

Most scooter companies are shipping scooters with Battery Packs assembled in India.

Here are examples of Lithium battery makers who have a pretty decent presence in Indian electric scooter market.- Trontek - Based out of NCR. They make battery packs for multiple scooter OEMs

- Okaya - Large battery maker who have Indian presence

- PureEV - Huge RnD being done on batteries, thermals, BMS and they make their own battery packs for their vehicles.

- Chargers

There was a time in 2016-17, when scooter companies found it competitive to import chargers from China. But not anymore. Multiple Indian companies are supplying Made In India chargers.- One example is Nuteck, a Pune based power electronics company that is supplying chargers to multiple OEM’s.

- PureEV the Hyderabad based startup makes their own chargers.

- Controllers

- The brain of an electric scooter. Many companies get dumb controllers mass manufactured in China. But progressive eScooter startups are creating controller algorithms and software here in India and they are either outsourcing manufacturing of controllers to China or they are tying up with Indian companies to make the boards.

- We know few OEMs are using Made In India controllers in some of their scooters or will launch scooters with Made in India controllers.

- Mechanical Parts

- Chassis, Tyres, Rims, wire harness all can be got from Indian suppliers and many scooter companies are localizing these mechanical components.

- Software

- Common! We are masters at software and many scooter companies are investing in RnD to make software for their vehicles.

What components have to be imported as of mid 2020?

- Battery Cells

These can be got from non Chinese sources until India makes cells locally. We have no cell manufacturing in India yet as of 2020.

These are large cell manufacturers in the world -- Tesla’s gigafactory makes most Li cells in the world.

- Panasonic, Samsung are two large Japanese and Korean makers of Li Cells.

- In coming few years we expect multiple large companies to make lithium cells in India - Tata Chemicals, Suzuki etc

- Motors

Motors have a more complex production. China has an economy of scale right now. And most electric scooters use Chinese motors.

But we are aware of few startups who will launch an electric scooter with a Made In India motor soon. - LED Lights & Plastic Moulds

- We got to know that it’s a challenge to get LED lights for scooters. So, many companies are importing from China. For some reason, China has economies of scale here and many of our EV companies are still getting plastic moulds from China.

We spoke about Chinese bus OEMs like Foton and BYD. They are setting up investments in India and creating EV products for India.

Same can be said of scooter and car manufacturers like - Gemopai, Benling, Great Wall Motors, MG Motors.

Is this a good thing?

- They are generating employment in India

- They are creating Electric Vehicles which will benefit Indian cities by not creating air pollution and also enable us to import less oil.

- Issue, is they will send profits back to China

- Maybe they should not be allowed to sell pollution vehicles. For Example MG Motors launched a pollution car called Hector. Why does India need more oil guzzling SUVs?

Can these Chinese OEMs be barred from selling pollution vehicles?

As you see from the below points and the links embedded. The solar, pharma, mobile phone, and even the ICE Vehicle industries are dependent on China.

- Indian Pollution Vehicle industry also import components from China and they don’t want to boycott Chinese imports.

- Adani says it will take 3 to 5 years to get rid of Chinese dependency in Solar industry

- Relied on China for Solar Cells.

- Production cost was Rs 24. They were selling at Rs 21 in India

- RealMe is a Chinese company but they have a mobile phone assembling plant in India. They still have only localised upto 60% and are still dependent on China

- The Indian pharma industry is heavily dependent on China. At least 65% of India's Active Pharmaceutical Ingredient (API) requirements come from China.

So as you can see, our EV industry is way ahead of the game in terms of localisation and we can wean ourselves away from China faster than all these other industries like Solar, Phones, Consumer Electronics. And you also saw how the ICE vehicle industry is dependent on China. If you are buying a pollution vehicle and then too you are sending money to China.

There are other industries that have more dependency on China than the EV industry.

The entire argument that Electric Vehicles = China dependency is wrong. People who are making these statements have an agenda against EV's or they are misguided.

We need to have venture capitalists with deep pockets. Two examples that come to mind are: Reliance and the Government of India. We must remember that Indian car making went into boost mode only after the Govt funded Maruti now Suzuki. We need to get customers addicted to electric vehicles at low prices. Later on price increases can happen. With its distorted FAME subsidy, applicable only to the higher priced high speed vehicles, the Indian government is not helping the cause of electrification.

Some protection barriers will also need to be set up. Allow import of components but not assembled vehicles. Not only will this encourage the EV industry, but it will also lead to job creation. A case study is the US where lack of protection has led to a total wipe out of US manufacturing jobs. Refer to this article by Andy Grove - the late CEO of Intel.

Another case study which is worth looking at is the solar panel industry. The lone Indian star in this field is Adani, which has a solar cell manufacturing plant. But all their production is for captive consumption. The good news is that the valuation of the solar company is now more than the valuation of their ports company. In spite of having started cell assembling units, most Indian companies could not survive the Chinese onslaught. Chinese players priced cells way above assemblies, driving out a lot of desi players. Even European behemoth Bosch had to shut down its solar cells plant in face of the price war launched by the government backed Chinese players. Classical game theory has now made incumbent battery players to stay away from manufacturing battery cells for the same reason.

Imitation is the best form of flattery. And Indian manufacturers have flattered the Chinese enough for the first 10 years. Most sellers today are still what we call container-rajas. Buy China, Sell India. Yet imitation could have played out differently. You do need a base when you start from scratch, but you need to build on that base. Case in point is Tesla’s first model - the Roadster, which was simply a refurbished Lotus. Even Space X’s initial rocket designs were blatantly Russian.

The initial attempts by the big IC engine Indian automakers to electrify were quite sad. TVS launched its first electric scooty in 2012. It was basically a jugaad made of their existing Scooty, retrofitted with Chinese parts. It was a lemon, and a sluggish one at that, with a range of just 30 km. Needless to mention, it died a natural death in a matter of months. TVS Motors did not even bother to give service support after a year. TVS was fortunate; the launch was limited to a few cities - and very few vehicles. So they did not have to face too much of a consumer backlash. Now when it comes to re launching electric again, the first thought that came to mind for TVS was to have an electric Jupiter. But the Scooty experience dictates that brand Jupiter needs to be saved from any pitfalls in product quality.

In contrast, the Bajaj story is different. We are very happy with the fit and finishes on the Chetak. But we have to be realistic, this is the minimal expectation that a customer would have had from an established player like Bajaj. No extra marks for that. A metal body gives a feeling of ruggedness to the vehicle. The only problem with the Chetak is the brand. It will not have any appeal to the young. Anybody who is less than 35 years old, would associate Chetak as a scooter of an earlier generation. The only ones who will have positive associations are guys in their forties and fifties - not exactly the target segment that Bajaj may have in mind. Maybe they could have gone with slightly more contemporary design and contemporary brand. The good news is that they seem to have enough bookings in their kitty. It’s players like Bajaj who are going to show the way forward to the EV industry. It’s players with deep pockets like Bajaj that will need to take initiative in high capex areas like Li cell manufacturing, not just for themselves, but for the Indian EV industry. They can learn a lesson from Dhirubhai Ambani that backward integration can give scale.

There seems to be an anti China movement in India because of China's expansionist policies and The CCP seems to have an attitude of mistrust/conflict towards India.

Then what about the USA. Their military industrial complex has thousand military bases globally and is waging “regime change” wars in so many countries.

Should we also not buy from the USA too?

Where do we draw the line?

While we agree with Mr Sonam Wangchuk’s - Cheen ka jawaab wallet se dena hai, but ultimately we feel that we should go with a pragmatic approach.

- Our attitude should be "Pro India". It’s not about focussing about banning trade from China

- Our intent should be how to gradually localise and manufacture in India.

- We can also look for alternatives apart from Chinese sources.