by Johnson

If you think about the the time we used to marvel at the introduction of Pentium 1 processor on desktop PCs to today where QuadCore processors have become common on smartphones, its been a long walk… a hell of a long walk.

And right through, the tech world has seen a plethora of innovations like development of USB Ports, Wi-Fi connectivity, 15,000 RPM Hard Disk Drives, Terabyte External HDD that can fit inside your shirt pocket, CD, DVD, BlueRay, thinner laptop, digital cameras, iPod, development of the mobile phone, smartphones that share the same features as the desktop PCs, Tablet PC and now Smart Watches.

Right through these 2 decades, battery technology made certain discoveries but they were never really implemented in to any mainstream products except for Li-Ion for laptop, cameras and mobile phones. This remained true for almost a decade. And the price of the Li-Ion battery fell by about 4 times but it still remains very high. Battery technology till now was struggling to keep up with the advances in hardware.

And right through, the tech world has seen a plethora of innovations like development of USB Ports, Wi-Fi connectivity, 15,000 RPM Hard Disk Drives, Terabyte External HDD that can fit inside your shirt pocket, CD, DVD, BlueRay, thinner laptop, digital cameras, iPod, development of the mobile phone, smartphones that share the same features as the desktop PCs, Tablet PC and now Smart Watches.

Right through these 2 decades, battery technology made certain discoveries but they were never really implemented in to any mainstream products except for Li-Ion for laptop, cameras and mobile phones. This remained true for almost a decade. And the price of the Li-Ion battery fell by about 4 times but it still remains very high. Battery technology till now was struggling to keep up with the advances in hardware.

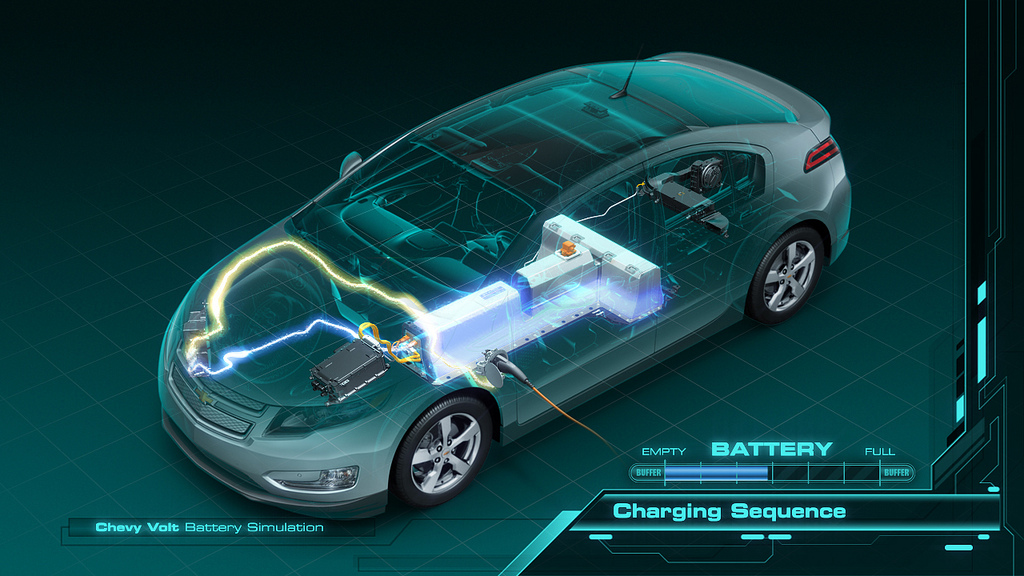

These mobile phone companies have increasingly started to look at how to extend the battery time and how to decrease the charging time. What they have on the horizon is quite exciting… not only for the Smartphone market but also for the Electric Car makers and enthausiast. There are not only new battery technologies but also finding ways how charging time can be decreased just by software upgrades.

Since the Smartphone makers are sure to implement some of these technologies the Electric Car Market will be the immediate and biggest beneficiary. Not all car makers are manufacturing battery, but implementing some of the below ideas into their manufacturing unit could be a big boon for them.

StoreDot, Tel Aviv University’s nanotechnology department, an Israeli start-up, has found a way to fuel a Galaxy S4 in just 30 seconds. They demo-ed its new battery on a Galaxy S4 at Microsoft’s Think Next Conference. The company says it’s “not quite there yet” and we have to wait for warp speed charging on our phones until 2016, but the technology is promising.

The phone charger which is about the size of a laptop charger, and could cost about $30 is quite different from the lithium-ion batteries. It is based on biological semiconductors, which are made from naturally organic compounds called peptides. In the human body, peptides perform hormonal activities and signaling functions.

StoreDot claims that its phone charger can prolong the existence of your battery pack because it can “withstand thousands of charge/discharge cycles, prolonging battery life considerably.”

The phone charger which is about the size of a laptop charger, and could cost about $30 is quite different from the lithium-ion batteries. It is based on biological semiconductors, which are made from naturally organic compounds called peptides. In the human body, peptides perform hormonal activities and signaling functions.

StoreDot claims that its phone charger can prolong the existence of your battery pack because it can “withstand thousands of charge/discharge cycles, prolonging battery life considerably.”

Eesha Khare’s Supercapacitor

Eesha Khare, has created a Super-capcitor that can fully charge a battery in — count ‘em — as little as 30 seconds.

Eesha Khare is an American student of Indian origin who is an 18-year-old graduate of Lynbrook High School in California and was the runner up at Intel International Science and Engineering Fair held in Phoenix on May 17, 2013 where 1,600 other finalists from more than 70 countries participated

The soon-to-be Harvard student entered her innovation into this year’s Intel International Science and Engineering Fair, in which she was named one of three winners, earning her a cash prize of $50,000. The technology that she created may even help power electric cars.

It’s so sophisticated that, despite keeping tight lips on the ordeal, Khare has been approached by Google, which has shown some serious interest.

As presented at the science fair, her creation charges an LED, but she says that it is flexible. It can easily adapt so that it can be used in flexible displays and even in fabric. Right now, it can hold 10,000 recharging cycles, which is far better from the standard rechargeable battery, which can only withstand around 1,000.

As of now, Khare says she plans to use her prize money to help fund her education at Harvard, where she hopes to continue researching her project. But she currently has no plans to sell her technology, though it seems like she is keeping her options open.

I hope Mahindra Reva guys can fund her education and appoint her as their battery development technology head. Mahindra EVs could sell all over the planet! Here is her video:

Eesha Khare, has created a Super-capcitor that can fully charge a battery in — count ‘em — as little as 30 seconds.

Eesha Khare is an American student of Indian origin who is an 18-year-old graduate of Lynbrook High School in California and was the runner up at Intel International Science and Engineering Fair held in Phoenix on May 17, 2013 where 1,600 other finalists from more than 70 countries participated

The soon-to-be Harvard student entered her innovation into this year’s Intel International Science and Engineering Fair, in which she was named one of three winners, earning her a cash prize of $50,000. The technology that she created may even help power electric cars.

It’s so sophisticated that, despite keeping tight lips on the ordeal, Khare has been approached by Google, which has shown some serious interest.

As presented at the science fair, her creation charges an LED, but she says that it is flexible. It can easily adapt so that it can be used in flexible displays and even in fabric. Right now, it can hold 10,000 recharging cycles, which is far better from the standard rechargeable battery, which can only withstand around 1,000.

As of now, Khare says she plans to use her prize money to help fund her education at Harvard, where she hopes to continue researching her project. But she currently has no plans to sell her technology, though it seems like she is keeping her options open.

I hope Mahindra Reva guys can fund her education and appoint her as their battery development technology head. Mahindra EVs could sell all over the planet! Here is her video:

Korea Advanced Institute of Science and Technology (KAIST), South Korea have developed a patch-like ‘glass fabric’ thermoelectric (TE) generator that rests on a person’s skin, converting their body heat into electricity.

According to Phys.org, KAIST’s creation is of particular interest as it improves on current TE generators in two ways. Existing organic-based TE generators, for example, are flexible but have a disappointing power output, while inorganic-based TE generators have better performance but are rigid and bulky. KAIST’s work, however, has produced a product that’s not only light and flexible, but also minimizes thermal energy loss while maximizing power output.

According to Phys.org, KAIST’s creation is of particular interest as it improves on current TE generators in two ways. Existing organic-based TE generators, for example, are flexible but have a disappointing power output, while inorganic-based TE generators have better performance but are rigid and bulky. KAIST’s work, however, has produced a product that’s not only light and flexible, but also minimizes thermal energy loss while maximizing power output.

KAIST have also managed to extend the reach of wireless power transfer technology. The new technology, called “Dipole Coil Resonant System (DCRS),” can charge up to 40 smartphones simultaneously from 5 meters away. The DCRS transfers electric power wirelessly through the use of transmitters and a specially designed coil structure.

Qualcomm’s Quick Charge 2.0 is an in-device charging technology which is making its way into devices and wall chargers. It can charge any devices up to 75 percent faster than those without it. It improves upon its predecessor, Quick Charge 1.0, which recharged 40-percent quicker. The technology can be found in Snapdragon 800-powered smartphones and tablets.

Check out the video below:

Check out the video below:

Leyden Energy’s Li-imide is an evolutionary step forward, and can provide three times the lifecycle of lithium ion cells. However, lithium imide also works with other materials such as silicon, which is considered to be the next big thing in battery technology, and could see us armed with batteries that last up to a week and recharge in 15 minutes. And because of Li-imide’s versatility the company’s research into silicon anodes is“progressing at a faster rate than others” and should be available between 2015 to 2016.

Leyden Energy is differentiating itself from other battery manufacturers in another way too, as it has taken the unusual step of working incredibly closely with hardware manufacturers right from the start, to create high performance batteries optimized for a particular product. They like to get into the design process so that they can have more impact as an interaction which goes far deeper than you’d imagine, with everything from fine tuning charging algorithms to custom tailoring the battery to give a longer runtime.

Traditionally, battery manufacturers sell off-the-shelf designs and aren’t interested in limited runs required for new product development. It’s this pro-activeness and attention to detail that sets Leyden Energy apart, and could well pay dividends in the future.

Traditionally, battery manufacturers sell off-the-shelf designs and aren’t interested in limited runs required for new product development. It’s this pro-activeness and attention to detail that sets Leyden Energy apart, and could well pay dividends in the future.

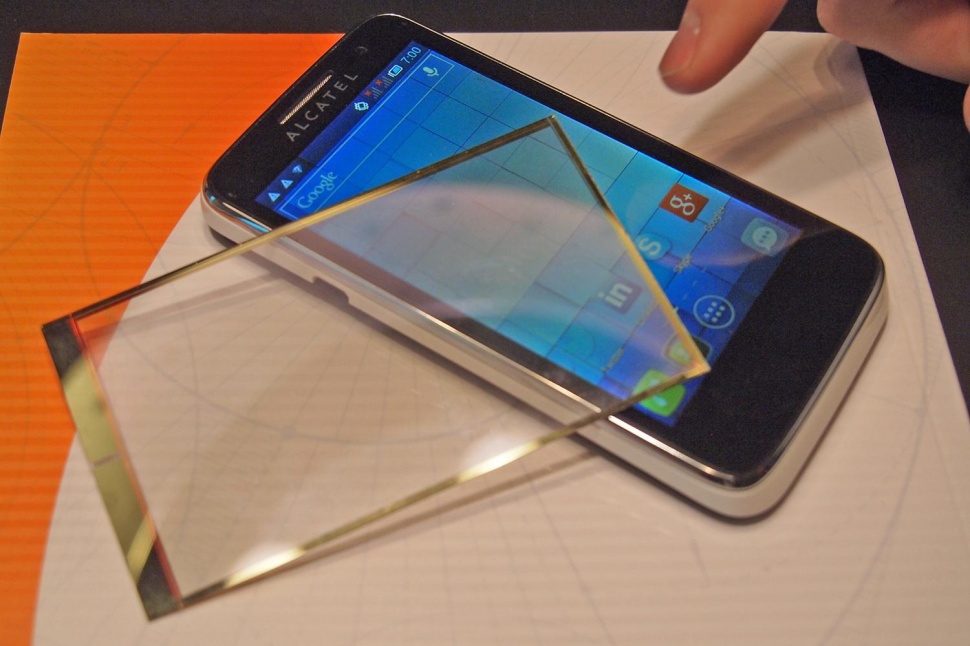

Wysips Solar charging

SunPartner have developed a deviced called “Wysips Screen Layer” which is a thin layer of crystal glass that can be embedded into small screens like watches, phones, tablets or even car windows and turn the screen into a solar panel of sorts. You can’t see it from the outside of the phone (it’s just about completely clear) and it starts charging the battery anytime artificial or natural light shines on the phone’s screen.

This technology could one day make chargers obsolete.

Every time it gets light, it will charge over the period of a day or night (and sourcing from indoor lighting) it could top up the battery by 15%. If this technology was to be implemented in Electric Vehciles then the windows it could top up 25% to 30% of the battery from direct sunlight during the day and 10 to 15% from street light at night. This would add about 30 to 40% increase in the charge of a car battery within 24 hrs!!!

SunPartner makes the screen layer and 3M creates the adhesive needed to put it in screens, and helping it reach manufacturers and get some press from publications.

Check out the Wysips Layer video below:

SunPartner have developed a deviced called “Wysips Screen Layer” which is a thin layer of crystal glass that can be embedded into small screens like watches, phones, tablets or even car windows and turn the screen into a solar panel of sorts. You can’t see it from the outside of the phone (it’s just about completely clear) and it starts charging the battery anytime artificial or natural light shines on the phone’s screen.

This technology could one day make chargers obsolete.

Every time it gets light, it will charge over the period of a day or night (and sourcing from indoor lighting) it could top up the battery by 15%. If this technology was to be implemented in Electric Vehciles then the windows it could top up 25% to 30% of the battery from direct sunlight during the day and 10 to 15% from street light at night. This would add about 30 to 40% increase in the charge of a car battery within 24 hrs!!!

SunPartner makes the screen layer and 3M creates the adhesive needed to put it in screens, and helping it reach manufacturers and get some press from publications.

Check out the Wysips Layer video below:

The Wysips layer is mostly cost neutral, costing only $2 to $3 dollars (possibly less) to include inside a phone screen – much less than many new technologies. This means it’s cost is already relatively low, and it could make it into a number of devices in the next few years. It’s not just a cool technology – it’s one that may see the light of day.

Bigger the surface higher the charge… the biggest screen size I can think of is my car windshield screen!... and there 2 of them front and rear… and a total of 4 smaller ones on the sides… total surface area is huge!

If this screen works indoors it would definitely be possible for it to add at least 20% in at least 4 to 6 hours in the sun. Windows of cars were a kind of tricky area to put solar panels… you either had to make the windows of the car smaller which would make the car interior seem smaller than it really is or you could only use panels as sunshades after parking the car. But with this technology the car could charge on the move and even when parked. Amazing!

Bigger the surface higher the charge… the biggest screen size I can think of is my car windshield screen!... and there 2 of them front and rear… and a total of 4 smaller ones on the sides… total surface area is huge!

If this screen works indoors it would definitely be possible for it to add at least 20% in at least 4 to 6 hours in the sun. Windows of cars were a kind of tricky area to put solar panels… you either had to make the windows of the car smaller which would make the car interior seem smaller than it really is or you could only use panels as sunshades after parking the car. But with this technology the car could charge on the move and even when parked. Amazing!

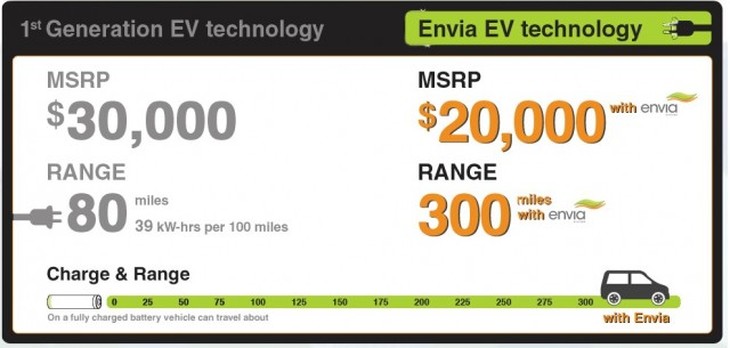

Envia Battery Technology - Hopes are still alive

Envia Battery Technology is the brainchild of Sujeet Kumar, an Indian gifted in electrochemistry. Using the NMC cathode, Kumar decided to pair it with a new silicon anode, also developed by Argonne, that didn't swell and damage the battery under charging. Combining the two could deliver 400 watt-hours per kg of energy density-enough for a 300 mile battery at half the current cost. A prototype of this battery was made and it returned the desired characteristics.

Envia Battery Technology is the brainchild of Sujeet Kumar, an Indian gifted in electrochemistry. Using the NMC cathode, Kumar decided to pair it with a new silicon anode, also developed by Argonne, that didn't swell and damage the battery under charging. Combining the two could deliver 400 watt-hours per kg of energy density-enough for a 300 mile battery at half the current cost. A prototype of this battery was made and it returned the desired characteristics.

Kapadia and Kumar before their misunderstanding. Kapadia was laid off in late August, filing his own lawsuit against Envia. Kumar alleges Kapadia wouldn't share information on the GM deal within the company--but official records suggest otherwise. Kumar also said he'd never promised technology to be used in working electric vehicles, but terms in GM's contract suggest they were expecting a product that could be used directly in its vehicles.

General Motors expected Envia would develop and provide the cathode for the next-gen Volt in 2015--with the aim of a 200-mile range and made a deal with them. But under repeated charging the mileage dropped. Kumar claimed that the technology is still in its infancy and would still need time to work it out to its full potential. He also claimed that the battery that he had developed was not intended for specific use like in vehicles. This led to litigation among many parties involved. This technology is also being developed by ARPA-E. This technology is still at least 2yrs from successful implementation.

Currently, Envia is still researching new battery tech, winning a $3m DoE grant and looking into silicon-carbon anode technology.

Currently, Envia is still researching new battery tech, winning a $3m DoE grant and looking into silicon-carbon anode technology.

Final Words

The mind just boggles at the kind of work being done by the world's best minds on battery research. Over the next few years this search for a better battery technology will turn more competitive, intense and more exciting. This will only help the EV industry! So by the end of 2020 dont be surprised if you are offered an Electric Car with 400km range and takes just 5 to 10 minutes for recharge.

The mind just boggles at the kind of work being done by the world's best minds on battery research. Over the next few years this search for a better battery technology will turn more competitive, intense and more exciting. This will only help the EV industry! So by the end of 2020 dont be surprised if you are offered an Electric Car with 400km range and takes just 5 to 10 minutes for recharge.