By Team PluginIndia

Raphae speaks to Mr Syed Mubasheer, who is founder of DESPAT, a Chennai based company, who has been working on battery pack design, high capacity polymer battery solutions & large scale Li-Ion batteries for more than a decade. And recently Mr. Syed also founded a new startup called Cellestial E-Mobility, which aims to create high performance commercial EVs.

Raphae speaks to Mr Syed Mubasheer, who is founder of DESPAT, a Chennai based company, who has been working on battery pack design, high capacity polymer battery solutions & large scale Li-Ion batteries for more than a decade. And recently Mr. Syed also founded a new startup called Cellestial E-Mobility, which aims to create high performance commercial EVs.

Video Interview - Electric Tractor & Lithium Battery : Cellestial E-Mobility & Despat

Raphae :

Welcome to another episode of Let's Chat on the PluginIndia channel. In this episode of Let's Chat, We speak to Mr. Syed Mubasheer who is the founder of Despat a Chennai based the company who has been working on battery pack design and high capacity polymer battery solutions and large-scale lithium-ion batteries for more than a decade recently Mr. Syed founded a new company a very interesting startup called Cellestial e-mobility which aims to create high performance electric vehicles now let's find out a little bit more about this Syedji, Welcome to the show.

Syed :

Thank you so much Raphae. Pleasure is all mine.

Raphae :

You always been doing very interesting things bringing news kinds of solutions and technologies to the electric vehicle industry tell us a little bit more about what does Despat offer regarding lithium-ion batteries?

Syed :

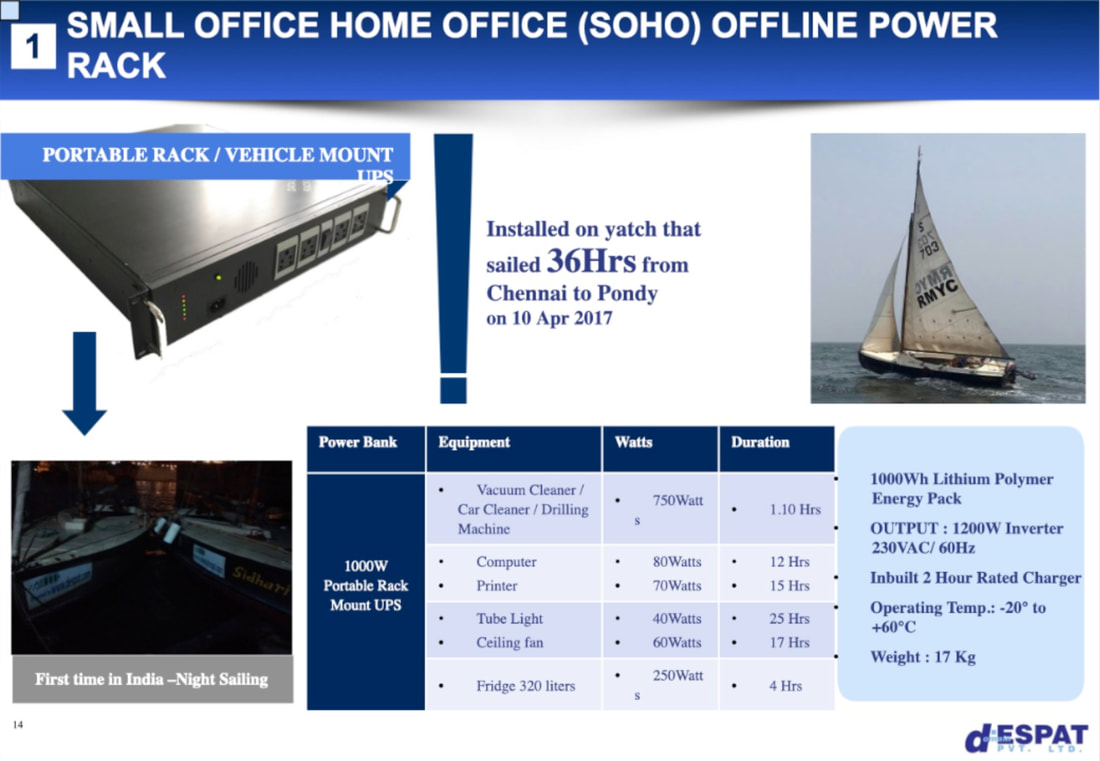

Despat is an MSME enterprise design shop for customized lithium-ion batteries. Our approach is to solve those projects that have a requirement for portable energy. We engage with customers that have a from the concept to production of solution that meets the requirements of their host device so that's what we are We are a boutique shop for custom lithium battery solution right so your clients can be from any sector not necessarily electric vehicles only. well we started off our journey basically to help Indian scientific labs like DSIR our CSIR have connected labs and several of the Indian defense labs like DRDO and our several others because those are the institutions that we are looking for these kind of solutions initially and through their help and support and patronage we've done quite a few projects then extended to other industries including commercial applications including telecom infrastructure telecommunication equipment commercial UPS solar renewable when I say UPS are here and there if you gradually became an extension to the electric mobility space that started happening somewhere around 2009-10 timeframe.

Raphae :

Can you give us an example of a project which uses the lithium-ion battery design.

Syed :

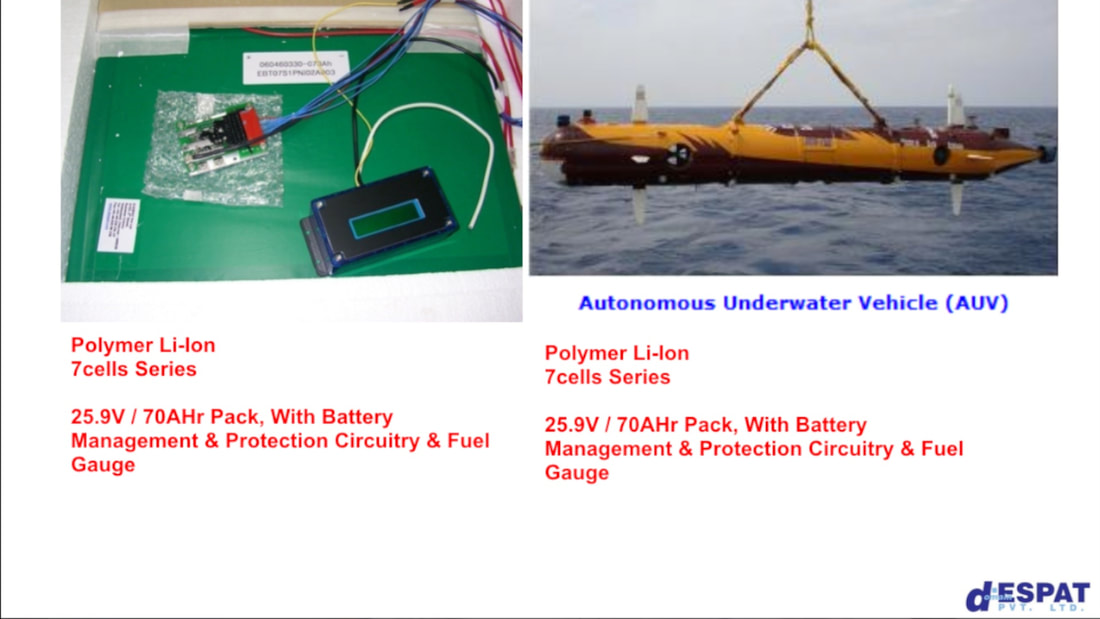

I like to talk about those projects which have been of real high value for example we did the project for a CSIR lab CMERI in Durgapur. They were making an autonomous underwater vehicle so we design help and build a product that goes into the hull of underwater device which is more like a submarine type of device it's a midget device and it's lasted for about seven eight years and both three years back they did their final testing for of the robust application of that AUV - an autonomous underwater vehicle. So it was a vehicle which had 2-4, 2-3 different types of battery systems in it and one was used for propulsion one was used for controlling the sensitive electronic equipment and a couple of them are used for talking to the remote setup on the on the ship so this was a unique experience and most of our experiences have been on building projects like these where customers have a very unique requirement and we fill in the gap of being the support system or partner in putting that product together. The product we support is basically the battery solution.

Welcome to another episode of Let's Chat on the PluginIndia channel. In this episode of Let's Chat, We speak to Mr. Syed Mubasheer who is the founder of Despat a Chennai based the company who has been working on battery pack design and high capacity polymer battery solutions and large-scale lithium-ion batteries for more than a decade recently Mr. Syed founded a new company a very interesting startup called Cellestial e-mobility which aims to create high performance electric vehicles now let's find out a little bit more about this Syedji, Welcome to the show.

Syed :

Thank you so much Raphae. Pleasure is all mine.

Raphae :

You always been doing very interesting things bringing news kinds of solutions and technologies to the electric vehicle industry tell us a little bit more about what does Despat offer regarding lithium-ion batteries?

Syed :

Despat is an MSME enterprise design shop for customized lithium-ion batteries. Our approach is to solve those projects that have a requirement for portable energy. We engage with customers that have a from the concept to production of solution that meets the requirements of their host device so that's what we are We are a boutique shop for custom lithium battery solution right so your clients can be from any sector not necessarily electric vehicles only. well we started off our journey basically to help Indian scientific labs like DSIR our CSIR have connected labs and several of the Indian defense labs like DRDO and our several others because those are the institutions that we are looking for these kind of solutions initially and through their help and support and patronage we've done quite a few projects then extended to other industries including commercial applications including telecom infrastructure telecommunication equipment commercial UPS solar renewable when I say UPS are here and there if you gradually became an extension to the electric mobility space that started happening somewhere around 2009-10 timeframe.

Raphae :

Can you give us an example of a project which uses the lithium-ion battery design.

Syed :

I like to talk about those projects which have been of real high value for example we did the project for a CSIR lab CMERI in Durgapur. They were making an autonomous underwater vehicle so we design help and build a product that goes into the hull of underwater device which is more like a submarine type of device it's a midget device and it's lasted for about seven eight years and both three years back they did their final testing for of the robust application of that AUV - an autonomous underwater vehicle. So it was a vehicle which had 2-4, 2-3 different types of battery systems in it and one was used for propulsion one was used for controlling the sensitive electronic equipment and a couple of them are used for talking to the remote setup on the on the ship so this was a unique experience and most of our experiences have been on building projects like these where customers have a very unique requirement and we fill in the gap of being the support system or partner in putting that product together. The product we support is basically the battery solution.

Raphae :

Syedji what kind of battery chemistry would we generally, work with, in these battery packs, is it NMC and your choice of lithium polymer we know about why is that something that you choose?

Syed :

Okay so we basically, compete where the battery weight, volume, and footprint has to be tailor-made for the customer and this is very critical for the customer's post devices to be successful and somehow the best chemistry that's sort of foots this bill is the NMC most of the time so it was just that by chance we were getting opportunities more around this the technology we have been familiar with the others, the LFP, and others but some of the products it was coming our way was around this Technology.

Raphae :

In your experience, you must have a lot of information basically about lithium cell manufacturers and where they are around the world where do you generally source your cells from and which are the good manufacturers according to you which offer good quality cells?

Syed :

Well, there are many cell manufacturers in the globe basically as scouting for our boutique services we have got cells from the US, from Germany, from Korea, Taiwan and China in the order of this priority now when I say priority basically customers which look for very high performance expectations we've looked at sources where the plants which manufacture these cells have some sort of a semi automation or automation in their manufacturing capability because then we buy cells they are very consistent we can buy in small quantities and build battery packs which are of really high value. See, I like to tell a little about how we build or what kind of products we undertake Raphae. We work on what we call as a M.E.B. formula so M.E.B. stands for a Mission first, Equipment next, Battery lasts in critical. So, if our customer was walking to us has this kind of a priority of his project then we are on this project with them. If the project priorities reverse the battery cost is a first and very conscious we as a small enterprise, we as an enterprise can't sort of meet the aspirations of giving them a cost-effective solution and that's how we have developed our capabilities of building these different unique solutions of the last 17 years.

Raphae :

So, while you do this works Syedji, do you also develop the BMS software and other features or are they off-the-shelf management systems that you use?

Syed :

Most of, see its been two decades that we are in this line so when we started our journey we developed partnerships with many friends who are interested in this line of work so we majorly work with our associates based out of Singapore, Hong Kong and quite a few of them in Shenzhen. We have developed domestically in Chennai as well as in Bangalore in other cities. A few solutions but some of our critical projects we work with somebody we are very familiar with and we are very confident in deliver the kind of product we want and was also very supportive in doing multiple reengineering of getting to what we actually need to get to deliver the specifications of the battery that we build.

Raphae :

Awesome! and a little bit about thermal management how do you control the temperature of the specs?

Syed :

So, Raphae ji, we are a portable energy system integrator so most of the customers who have come to us, require solutions for portable energy, portable applications, and most of the application that we have done so far in the Indian context are, which have small sorties when I say that which I mean anything from a 40 minutes playtime to maybe a few hours after that the vehicle or the host device is at rest there's a lot of time for him before the next engagement happens. So, in these kinds of projects, the customer does not want to have any kind of a parasite load and thermal is a parasitic load so when we want to build a product it has to be a small footprint and also has to give energy for a duration of the host device to operate we try to build systems which are very effective without thermal management that said when we went on to build a bigger project like we saw in the the river retrofits we have done we try to use the conventional cooling that is already there in the vehicle we've already had the lead acid battery already had this capability so you use that to design our system so that we don't have to look for additional ways of managing the turbines even when it is the India which is the long-distance vehicle we try to take advantage of the same setup so that we don't have additional loads to drain off our battery others it was impossible to drive for 460 - 470 kilometers with this additional loads so some come to us with requirements that that need probably liquid cooling we haven't gotten to that space yet because either the customer backs off once you tell them the timelines and the project cost which is fair it's understandable but we haven't got that kind of opportunity yet but it's not that it is not doable.

Raphae :

Right! You also develop some enclosures have you developed enclosures for these battery packs?

Syed :

Raphae ji, all the time the whole suite of putting the battery pack together is our responsibility so we call ourselves integrators which means we work with the customers host device finding out the space that he allocates and we build the battery pack with the right packaging whether because in plastics or metals or whatever with the right kind of shielding and other qualification that he wants appropriate to his host device and then we deliver the full product which he can just plug and play into his system that's how we do most of the time.

Syedji what kind of battery chemistry would we generally, work with, in these battery packs, is it NMC and your choice of lithium polymer we know about why is that something that you choose?

Syed :

Okay so we basically, compete where the battery weight, volume, and footprint has to be tailor-made for the customer and this is very critical for the customer's post devices to be successful and somehow the best chemistry that's sort of foots this bill is the NMC most of the time so it was just that by chance we were getting opportunities more around this the technology we have been familiar with the others, the LFP, and others but some of the products it was coming our way was around this Technology.

Raphae :

In your experience, you must have a lot of information basically about lithium cell manufacturers and where they are around the world where do you generally source your cells from and which are the good manufacturers according to you which offer good quality cells?

Syed :

Well, there are many cell manufacturers in the globe basically as scouting for our boutique services we have got cells from the US, from Germany, from Korea, Taiwan and China in the order of this priority now when I say priority basically customers which look for very high performance expectations we've looked at sources where the plants which manufacture these cells have some sort of a semi automation or automation in their manufacturing capability because then we buy cells they are very consistent we can buy in small quantities and build battery packs which are of really high value. See, I like to tell a little about how we build or what kind of products we undertake Raphae. We work on what we call as a M.E.B. formula so M.E.B. stands for a Mission first, Equipment next, Battery lasts in critical. So, if our customer was walking to us has this kind of a priority of his project then we are on this project with them. If the project priorities reverse the battery cost is a first and very conscious we as a small enterprise, we as an enterprise can't sort of meet the aspirations of giving them a cost-effective solution and that's how we have developed our capabilities of building these different unique solutions of the last 17 years.

Raphae :

So, while you do this works Syedji, do you also develop the BMS software and other features or are they off-the-shelf management systems that you use?

Syed :

Most of, see its been two decades that we are in this line so when we started our journey we developed partnerships with many friends who are interested in this line of work so we majorly work with our associates based out of Singapore, Hong Kong and quite a few of them in Shenzhen. We have developed domestically in Chennai as well as in Bangalore in other cities. A few solutions but some of our critical projects we work with somebody we are very familiar with and we are very confident in deliver the kind of product we want and was also very supportive in doing multiple reengineering of getting to what we actually need to get to deliver the specifications of the battery that we build.

Raphae :

Awesome! and a little bit about thermal management how do you control the temperature of the specs?

Syed :

So, Raphae ji, we are a portable energy system integrator so most of the customers who have come to us, require solutions for portable energy, portable applications, and most of the application that we have done so far in the Indian context are, which have small sorties when I say that which I mean anything from a 40 minutes playtime to maybe a few hours after that the vehicle or the host device is at rest there's a lot of time for him before the next engagement happens. So, in these kinds of projects, the customer does not want to have any kind of a parasite load and thermal is a parasitic load so when we want to build a product it has to be a small footprint and also has to give energy for a duration of the host device to operate we try to build systems which are very effective without thermal management that said when we went on to build a bigger project like we saw in the the river retrofits we have done we try to use the conventional cooling that is already there in the vehicle we've already had the lead acid battery already had this capability so you use that to design our system so that we don't have to look for additional ways of managing the turbines even when it is the India which is the long-distance vehicle we try to take advantage of the same setup so that we don't have additional loads to drain off our battery others it was impossible to drive for 460 - 470 kilometers with this additional loads so some come to us with requirements that that need probably liquid cooling we haven't gotten to that space yet because either the customer backs off once you tell them the timelines and the project cost which is fair it's understandable but we haven't got that kind of opportunity yet but it's not that it is not doable.

Raphae :

Right! You also develop some enclosures have you developed enclosures for these battery packs?

Syed :

Raphae ji, all the time the whole suite of putting the battery pack together is our responsibility so we call ourselves integrators which means we work with the customers host device finding out the space that he allocates and we build the battery pack with the right packaging whether because in plastics or metals or whatever with the right kind of shielding and other qualification that he wants appropriate to his host device and then we deliver the full product which he can just plug and play into his system that's how we do most of the time.

Raphae :

We remember from earliest experiences with you in the Mahableshwar rally that you converted Reva electric cars into better Reva electric cars by replacing the Lead-Acid with Lithium Polymer battery. We remember in 2016 we had such a good time with the car which we called "Poly" because of Lithium Polymer being in it and later on how you develop the Endura, which was 450 plus kilometer range which was absolutely mind-blowing from Bengaluru to Chennai to Mahabalipuram and I suppose part of the way back. Would your team consider doing more such create creative conversions?

Syed :

Raphae ji, I think we would love to do this kind of work we have been doing not only in the Reva conversion we had a lot of universities go Ev racing across the globe. We have worked with IIT we work with VIT Vellore or we put several institution in and around. We have students which is a team over 25 to 40 university kids who put these products together

We have built battery packs to the definition of their rule books and they've got registerations. Coming back to Reva we did a few after our 2016 trip to Pune and back there was the time we were testing our own product build and do we have lot of interest from the community the thing is that cost is an innovation I think so we have done about eight to ten retrofits to friends in Bangalore and a couple of them in Mysore beyond that we've not doing it commercially as a service. 2 reason one is basically doing for those who love their Reva they want to continue using it but they want to get away from the maintenance hassles of, you know watering Lead-acid batteries so we've done a few. At this point the cost is a little bitter maybe once we get access to good quality cells which we will test, abuse, approve, and then we'll come back and say hey we can do some more but till the time I think it's gonna be in the backfoot. So, waiting for technology to catch up a little bit.

Raphae :

Alright, Syed ji let's move on to something that you recently done let's talk about Cellestial e-mobility that's the start up which you've just founded and what is the vision behind this startup tell us briefly about this.

Syed :

Basically, it's a coming of two friends together which is Cellestial. I caught up with my friend so that about a year and a half December 2018 to be precise 22-year gap so it was just a break first meet at my place with coffee and we do two things which have some sort of commonness one is I'm in this engineering space where I do lithium batteries and the other thing that I do is I am into a product design costing I serve as a cost consultant. He has a knowledge based engineering capability as a company so we said and of course we have a common interest in the electric mobility space long story short the brainstorming said led to, let us go build something which is going to be offer industrial engineering capability something that has meaning that can probably get deployed in a domain where there is high value and probably good recognition for the sort of energy or fuel consumption that would probably be saved from running something which is electric viz-a-viz fossil fuel so this brainstorming led to the initial idea of what we called as a-hauler or advanced hauler then to the idea conception became metamorphosis, metamorphosis to say an airport hauler because we thought that's an opportunity where there is a lot of green and aqua culture and it's related to thinking that yes I think should build something which is in this fraction format so it became a tractor that's how this thing happened over the few months.

Raphae :

Wow so you are right about the fuel part is there is cheap electricity available that will definitely reduce the burden on the farmer and as far as you mentioned it was very quiet is that a factor and does the performance and maneuverability of this vehicle also improve?

Syed :

So from the user experience in a first product build we have not changed that attribute for example I would love to build an electric vehicle without the gearbox and all the shifting of gears but in this first product we have all of that available so that if you give it to a tractor operator you should feel the same have the same kind of experience in driving the vehicle okay so it's got zero turn everything is there. Going forward when we build our POST 2 and 3 we'll probably try to get rid of some more elements which are probably the gearbox and probably couple the motor to the vehicle's transmission directly because individually we want to build a product that is going to be even cost effective so that's an aspiration we have to get there we have to do a lot of things which are unconventional.

We remember from earliest experiences with you in the Mahableshwar rally that you converted Reva electric cars into better Reva electric cars by replacing the Lead-Acid with Lithium Polymer battery. We remember in 2016 we had such a good time with the car which we called "Poly" because of Lithium Polymer being in it and later on how you develop the Endura, which was 450 plus kilometer range which was absolutely mind-blowing from Bengaluru to Chennai to Mahabalipuram and I suppose part of the way back. Would your team consider doing more such create creative conversions?

Syed :

Raphae ji, I think we would love to do this kind of work we have been doing not only in the Reva conversion we had a lot of universities go Ev racing across the globe. We have worked with IIT we work with VIT Vellore or we put several institution in and around. We have students which is a team over 25 to 40 university kids who put these products together

We have built battery packs to the definition of their rule books and they've got registerations. Coming back to Reva we did a few after our 2016 trip to Pune and back there was the time we were testing our own product build and do we have lot of interest from the community the thing is that cost is an innovation I think so we have done about eight to ten retrofits to friends in Bangalore and a couple of them in Mysore beyond that we've not doing it commercially as a service. 2 reason one is basically doing for those who love their Reva they want to continue using it but they want to get away from the maintenance hassles of, you know watering Lead-acid batteries so we've done a few. At this point the cost is a little bitter maybe once we get access to good quality cells which we will test, abuse, approve, and then we'll come back and say hey we can do some more but till the time I think it's gonna be in the backfoot. So, waiting for technology to catch up a little bit.

Raphae :

Alright, Syed ji let's move on to something that you recently done let's talk about Cellestial e-mobility that's the start up which you've just founded and what is the vision behind this startup tell us briefly about this.

Syed :

Basically, it's a coming of two friends together which is Cellestial. I caught up with my friend so that about a year and a half December 2018 to be precise 22-year gap so it was just a break first meet at my place with coffee and we do two things which have some sort of commonness one is I'm in this engineering space where I do lithium batteries and the other thing that I do is I am into a product design costing I serve as a cost consultant. He has a knowledge based engineering capability as a company so we said and of course we have a common interest in the electric mobility space long story short the brainstorming said led to, let us go build something which is going to be offer industrial engineering capability something that has meaning that can probably get deployed in a domain where there is high value and probably good recognition for the sort of energy or fuel consumption that would probably be saved from running something which is electric viz-a-viz fossil fuel so this brainstorming led to the initial idea of what we called as a-hauler or advanced hauler then to the idea conception became metamorphosis, metamorphosis to say an airport hauler because we thought that's an opportunity where there is a lot of green and aqua culture and it's related to thinking that yes I think should build something which is in this fraction format so it became a tractor that's how this thing happened over the few months.

Raphae :

Wow so you are right about the fuel part is there is cheap electricity available that will definitely reduce the burden on the farmer and as far as you mentioned it was very quiet is that a factor and does the performance and maneuverability of this vehicle also improve?

Syed :

So from the user experience in a first product build we have not changed that attribute for example I would love to build an electric vehicle without the gearbox and all the shifting of gears but in this first product we have all of that available so that if you give it to a tractor operator you should feel the same have the same kind of experience in driving the vehicle okay so it's got zero turn everything is there. Going forward when we build our POST 2 and 3 we'll probably try to get rid of some more elements which are probably the gearbox and probably couple the motor to the vehicle's transmission directly because individually we want to build a product that is going to be even cost effective so that's an aspiration we have to get there we have to do a lot of things which are unconventional.

Raphae :

Syedji, what about you mentioned that it's reduction in the number of parts what exactly are the components of an electric tractor Syedji in broad terms at least?

Syed :

Okay generally I would say propulsion would have four systems it will have a motor, controller, battery, and the refueling charge which is the charger. Right! So the over and beyond this, you need to have these four wheels, You need to have the steering so that the vehicle can be maneuvered so from an anything propulsion perspective the whole engine block which has few hundreds of parts, is now just a single single motor, okay what is there is now being replaced by a little black box which is the fuel tank just the battery so we thought we'll add some elegance to the battery, we said we'll keep it swappable, we keep it with the capability to charge faster, we'll also give it a capability to charge from residential power so that if the idea of somebody to take them back home, from a 15-amp socket they should be able to charge the the same battery in about 6 to 7 hours. So, that's how we have build the vehicle.

Raphae :

Have you also done some research on how the farmers actually use them what their requirements are and what have you arrived at so far?

Syed :

So very interesting you ask that because when we started off this journey idea-ting and design thinking for the tractor. we were of the the impression that this a tractor user or the farmer or the operator starts in the morning in probably drive for 4-5 hours, calls it a day in the afternoon but that's not the case we attended as exhibitors with the idea of the selected tractor in few agricultural events professor farming events in Hyderabad in other places and when you talk to farmers saying hey if you have a tractor which is electric you can charge like this from your house residential power instead of spending say five-six hundred Rupees of fuel per day it will cost you about say eighty- hundred Rupees. Will that be interesting? So, while we were doing this survey we also found out that the farmers drives for a couple of hours before he takes a break before he goes on to the next activity or continuous driving so this kind of a thing gives us a chance to look at how we can build our product so we said the if two hours of intense work like plowing or tilling and there's a break then that's how he should probably sign our vehicle so we took this kind of inputs from different segments to put into this first product build we have more that is actually left as packages that we will probably bring into the second prototype and the third prototype going forward I mean we have some crazy and I would say crazy I think it's a possibility future requirements that we could have in the tractors for example you want to build the next vehicle without a steering wheel we want to have with the joystick drive, we want to have it with autonomy because you know most of the farmers today have a certain piece of land it could be geo-fenced you can let this tractor run and it just has to go in certain patterns and since it's a tractor I mean I'm talking about farming in particular I'm not talk of the other segments which is like airport hauling in others it goes in a certain it has a certain behavior or usage pattern we can build it and automate it then we can probably have tractors well you know if you row these little robots that you have at home. Right! so imagine the same thing I go in the morning and unplug my tractor from the charging port put in a particular Drive pattern and it goes around my field. I don't need an the operator that's fifteen-twenty thousand rupees of savings for a farmer. we understand per month so these kinds of conversations have actually helped us to bring in product ideas it's not there in the first product but going forward we're gonna have it I think when we build the prototypes.

Raphae :

That sounds absolutely mind-blowing Syedji, this would be a great revolution and I'm sure farmers will lap it up. Tell us a little bit about the kind of tractor you design like for instance in motorcycles you have segments where you have 100 CC segment 150CC segment certain more popular with the masses. What segment is this tractor going to be in?

Syed :

Okay Raphaeji, this first product build is a narrow gauge tractor which means we are looking at a 24, 21 to 25 HP speed tractor equivalence that is what we have built in this first prototype but what we understand is; this is basically for us to get a flavour see we have a team of 4 partners we have our own team members so we wanted to get a feel of how to build a product like this and we have done it fairly very nimbly, very quickly, in a matter of what 4.5 - 5 months which is I think a feat in itself but that said this is not the product which you can probably push or find the patronage spot because we understand most farmers have requirements where 30 HP and above 40, 35 HP or 45 HP tractors are the preferences for their whatever daily activities as they do around their their farms or subsequent post-production requirements so that's a way. You want to look at it probably would be in that segment that our next prototypes will aim to be built and we still don't know, having a good flavor of interest for this product itself so we'll wait for what the market says, we will wait for the customer segmentation that will happen but going forward we want to build a couple of prototypes will give us a better feel once we have a user using, experiencing this product.

Raphae :

How much do you think this will cost just a ballpark compared to what a diesel tractor would normally cost?

Syed :

So apart from the efforts we put on prototyping we have tried to put a bill of materials cost where-in at the factory floor it should probably cost us 5Lakhs this is the wishlist. We hope we will get there with some more intense engineering that you want to put to sort of achieve that. Do tell us a little bit about any real-life testing that you've done with some farmers and when will the product be ARAI or ICAC Certified So 2 things happened Raphae, one is this event I mean I referred to the 11th March we have this product launch and there's a pipeline of activity to be followed but as you know 12th, 13th onwards we have sort of a situation maybe we can't move it to a place where you conduct the subsequent test but we have some interest in Hyderabad and some friends who have mangroves. It's time for harvesting now, so probably we'll take it therewith permissions to see if we can try it out there we will be doing incremental tests internally before we go to the next level of getting certification from the right authorities we also are trying to read all the rules the part of how and what EV certifications for a format like this would be so that we can have it well prepared and with the right prototypes that can be sent to these agencies for certification.

Raphae :

Syedji we noticed that large manufacturers like say Mahindra or the John Deere of the world they are not very interested in making electric tractors now what you've seen from the electric vehicle segment is that the big car manufacturers don't generally want to shift very easily they're in there some sort of comfort zone. Do you think the the same thing is happening here with the farm equipment manufacturers

Syed :

Raphae ji, you're in a position of authority from PluginIndia, you know locked the industry compared to what we do but that said as an experience in this journey of building Cellestial and the product we got an opportunity interact with a few OEM heads, we understand they have their own limitations about how they see a product like this being realized well to some extent it probably would be their own you know foresight of how they want to take their business but you know disruption always happens from the outside I mean we don't have to say anything about electric mobility is a good case study of disruption from the outside. You know the time will tell about how we can probably be successful with a product like this there's no doubt that it won't be successful definitely, OEMs put their hearts to it they can achieve because they have the cloud, they have the reach, they have access in all places where they could push their products, service their product trained on the product if they build something like this. The question of why they're not doing it, is something that is left to our own imaginations well see what Cellestial can do in that space then

Raphae :

What are the milestones, this year for Cellestial?

Syed :

Considering that the current situation will ease out in the next month or so so as a team we wanted to build I mean if you get this product specification right which we will do eventually we want to be able to hundreds of them in the next four to six months Ofcourse! a lot of things on the pipeline that's another set of people who are looking at it. When you look at tractors per se I mean I'd like to give you the big picture and so Cellestial be one of the companies that wants to be an OEM in this space what 8,08,75,000 tractors have been sold in the last year and there's a good potential that a small portion of it can get electric in the next not one, if not two, in the next three years we want to have about 8000 tractors in about 3 years time. That's the vision. So how we get there everything is in packages in from now till this 36 months for the few hundreds of tractors in the right format or in some format that can probably get adopted in the next 6-9 months is in the plans.

Syed :

Syedji, now we have a few questions, the community at large has asked, we would like to put those across to you.

Syedji, what about you mentioned that it's reduction in the number of parts what exactly are the components of an electric tractor Syedji in broad terms at least?

Syed :

Okay generally I would say propulsion would have four systems it will have a motor, controller, battery, and the refueling charge which is the charger. Right! So the over and beyond this, you need to have these four wheels, You need to have the steering so that the vehicle can be maneuvered so from an anything propulsion perspective the whole engine block which has few hundreds of parts, is now just a single single motor, okay what is there is now being replaced by a little black box which is the fuel tank just the battery so we thought we'll add some elegance to the battery, we said we'll keep it swappable, we keep it with the capability to charge faster, we'll also give it a capability to charge from residential power so that if the idea of somebody to take them back home, from a 15-amp socket they should be able to charge the the same battery in about 6 to 7 hours. So, that's how we have build the vehicle.

Raphae :

Have you also done some research on how the farmers actually use them what their requirements are and what have you arrived at so far?

Syed :

So very interesting you ask that because when we started off this journey idea-ting and design thinking for the tractor. we were of the the impression that this a tractor user or the farmer or the operator starts in the morning in probably drive for 4-5 hours, calls it a day in the afternoon but that's not the case we attended as exhibitors with the idea of the selected tractor in few agricultural events professor farming events in Hyderabad in other places and when you talk to farmers saying hey if you have a tractor which is electric you can charge like this from your house residential power instead of spending say five-six hundred Rupees of fuel per day it will cost you about say eighty- hundred Rupees. Will that be interesting? So, while we were doing this survey we also found out that the farmers drives for a couple of hours before he takes a break before he goes on to the next activity or continuous driving so this kind of a thing gives us a chance to look at how we can build our product so we said the if two hours of intense work like plowing or tilling and there's a break then that's how he should probably sign our vehicle so we took this kind of inputs from different segments to put into this first product build we have more that is actually left as packages that we will probably bring into the second prototype and the third prototype going forward I mean we have some crazy and I would say crazy I think it's a possibility future requirements that we could have in the tractors for example you want to build the next vehicle without a steering wheel we want to have with the joystick drive, we want to have it with autonomy because you know most of the farmers today have a certain piece of land it could be geo-fenced you can let this tractor run and it just has to go in certain patterns and since it's a tractor I mean I'm talking about farming in particular I'm not talk of the other segments which is like airport hauling in others it goes in a certain it has a certain behavior or usage pattern we can build it and automate it then we can probably have tractors well you know if you row these little robots that you have at home. Right! so imagine the same thing I go in the morning and unplug my tractor from the charging port put in a particular Drive pattern and it goes around my field. I don't need an the operator that's fifteen-twenty thousand rupees of savings for a farmer. we understand per month so these kinds of conversations have actually helped us to bring in product ideas it's not there in the first product but going forward we're gonna have it I think when we build the prototypes.

Raphae :

That sounds absolutely mind-blowing Syedji, this would be a great revolution and I'm sure farmers will lap it up. Tell us a little bit about the kind of tractor you design like for instance in motorcycles you have segments where you have 100 CC segment 150CC segment certain more popular with the masses. What segment is this tractor going to be in?

Syed :

Okay Raphaeji, this first product build is a narrow gauge tractor which means we are looking at a 24, 21 to 25 HP speed tractor equivalence that is what we have built in this first prototype but what we understand is; this is basically for us to get a flavour see we have a team of 4 partners we have our own team members so we wanted to get a feel of how to build a product like this and we have done it fairly very nimbly, very quickly, in a matter of what 4.5 - 5 months which is I think a feat in itself but that said this is not the product which you can probably push or find the patronage spot because we understand most farmers have requirements where 30 HP and above 40, 35 HP or 45 HP tractors are the preferences for their whatever daily activities as they do around their their farms or subsequent post-production requirements so that's a way. You want to look at it probably would be in that segment that our next prototypes will aim to be built and we still don't know, having a good flavor of interest for this product itself so we'll wait for what the market says, we will wait for the customer segmentation that will happen but going forward we want to build a couple of prototypes will give us a better feel once we have a user using, experiencing this product.

Raphae :

How much do you think this will cost just a ballpark compared to what a diesel tractor would normally cost?

Syed :

So apart from the efforts we put on prototyping we have tried to put a bill of materials cost where-in at the factory floor it should probably cost us 5Lakhs this is the wishlist. We hope we will get there with some more intense engineering that you want to put to sort of achieve that. Do tell us a little bit about any real-life testing that you've done with some farmers and when will the product be ARAI or ICAC Certified So 2 things happened Raphae, one is this event I mean I referred to the 11th March we have this product launch and there's a pipeline of activity to be followed but as you know 12th, 13th onwards we have sort of a situation maybe we can't move it to a place where you conduct the subsequent test but we have some interest in Hyderabad and some friends who have mangroves. It's time for harvesting now, so probably we'll take it therewith permissions to see if we can try it out there we will be doing incremental tests internally before we go to the next level of getting certification from the right authorities we also are trying to read all the rules the part of how and what EV certifications for a format like this would be so that we can have it well prepared and with the right prototypes that can be sent to these agencies for certification.

Raphae :

Syedji we noticed that large manufacturers like say Mahindra or the John Deere of the world they are not very interested in making electric tractors now what you've seen from the electric vehicle segment is that the big car manufacturers don't generally want to shift very easily they're in there some sort of comfort zone. Do you think the the same thing is happening here with the farm equipment manufacturers

Syed :

Raphae ji, you're in a position of authority from PluginIndia, you know locked the industry compared to what we do but that said as an experience in this journey of building Cellestial and the product we got an opportunity interact with a few OEM heads, we understand they have their own limitations about how they see a product like this being realized well to some extent it probably would be their own you know foresight of how they want to take their business but you know disruption always happens from the outside I mean we don't have to say anything about electric mobility is a good case study of disruption from the outside. You know the time will tell about how we can probably be successful with a product like this there's no doubt that it won't be successful definitely, OEMs put their hearts to it they can achieve because they have the cloud, they have the reach, they have access in all places where they could push their products, service their product trained on the product if they build something like this. The question of why they're not doing it, is something that is left to our own imaginations well see what Cellestial can do in that space then

Raphae :

What are the milestones, this year for Cellestial?

Syed :

Considering that the current situation will ease out in the next month or so so as a team we wanted to build I mean if you get this product specification right which we will do eventually we want to be able to hundreds of them in the next four to six months Ofcourse! a lot of things on the pipeline that's another set of people who are looking at it. When you look at tractors per se I mean I'd like to give you the big picture and so Cellestial be one of the companies that wants to be an OEM in this space what 8,08,75,000 tractors have been sold in the last year and there's a good potential that a small portion of it can get electric in the next not one, if not two, in the next three years we want to have about 8000 tractors in about 3 years time. That's the vision. So how we get there everything is in packages in from now till this 36 months for the few hundreds of tractors in the right format or in some format that can probably get adopted in the next 6-9 months is in the plans.

Syed :

Syedji, now we have a few questions, the community at large has asked, we would like to put those across to you.

EV Community Questions

- Atul Gopal from PluginIndia

Many e2o electric car owners understand where their batteries are getting old. Many of us would like to get a new battery pack after using our cars for example, we would like we would look for a battery pack that can go around 150 kilometers so currently they e2os are 100-120 km and we have a group of 16 to 20 e2o owners who would like to get a new battery pack and Despat help create battery packs for these e2o's and what will it cost approximately?

Syed

Okay so 1st thing is if you get a replacement from anybody I don't think your warranties with the OEM will stand so that's the first risk that you are willing to sort of undertake and forgo Warranty 2nd thing is you can find these cells that could probably fit the existing battery space from the original OEM of these cells there a different cell manufacturers make it same format but the point would be to get cells with the exact dimensions so that it could be easily retrofitted what will happen is technology is involved so what I understand is same cell dimensions would probably have a higher capacity so when you have a high capacity individual cells hitting the same space you probably can achieve that 150 kilometer marker that you want but that's a little that's an exercise it's a it's a process in looking for a manufacturer finding a set of cells putting your product together testing it for whatever the user does and then establishing out and marking it and say hey this will do for example Reva took us about 6 months from lead-acid trying to understand what it does then stripping out the whole vehicle then finding what is the space available then finding a battery putting inside to put it inside it in the e2o would that will not be the case it is an LFe set cell there are few manufacturers who make that cell you can find similar cells with the Similar cell dimensions at higher capacity. Despat can do if you have a sort of a kick-start effort maybe PluginIndia should try that well now you get a crowd funding for what 20-30 people we can get BS VI certification and we can do a product which we can probably build and then give it to all of these enthusiasts who love the e2os. A battery is an energy storage it has to be carefully if you do one to one cell replacement then the of course there's a way of how you should approach and do that and then you can use the rest of the system of your vehicle as is. The charger, the intelligent onboard communication and battery management system everything can be used as is I personally have not touched the e2o yet many friends have asked right arey! You find out what get one repair as a matter of fact some friends in Bangalore have said I'll give you my e2o it's already not working and do you do even if it gets damaged while you try its ok. - Kamlesh from PluginIndia

Indian villages are small towns and villages and small towns have poor electricity connections do you think have an electric tractor will be advantageous to a farmer compared to him travelling far to get diesel and filling it in their diesel tractor.

Syed

So it's probably a myth that all the villages have bad quality electricity that said the I would say we would probably take these formats of vehicles to progressive farming communities 1st where, when I say progressive performing communities where these kind of things are already sort of well-established. The power is of high quality, the people believe in adopting newer ways of becoming having higher throughput and productivity. So that would be a 1st testing ground I mean any electric vehicle launched for that matter establishes this case right whether it's a scooter or a two wheeler it comes in two places like a Pune Delhi maybe Bombay and Bangalore you don't find them going to small towns and villages first right so that's a in the game plan and they'll be learnings from the field we will use that knowledge to build better and leaner and simpler solutions can we take into these low quality grid sites.

Thank you, Syed ji, that's well taken

We really enjoyed talking with you and chatting with you about various aspects of your Reva conversions, your new electric tractor project.

Thank you so much for sharing this with us.

Other Links

www.cellestial.com

We really enjoyed talking with you and chatting with you about various aspects of your Reva conversions, your new electric tractor project.

Thank you so much for sharing this with us.

Other Links

www.cellestial.com