There is that company EV lovers look up to. There is that company other EV companies yearn to emulate. There is that company that has admirers all over the world. There is that company that kick started the modern EV revolution. That company is Tesla Motors. The man who leads that company is Elon Musk.

Their products such as the Tesla Roadster and the Telsa Model S just kickass and are even scaring car companies who make their profits based on OIL based cars and are forcing them to launch EV's.

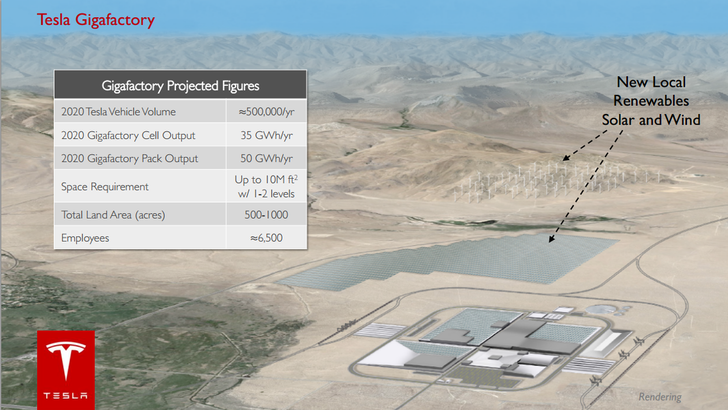

So when Tesla Motors announce massive plans, the industry notices. Tesla announced plans to setup massive factories to manufacture batteries, in a move that could lower the global prices of Lithium-Ion batteries.

Their products such as the Tesla Roadster and the Telsa Model S just kickass and are even scaring car companies who make their profits based on OIL based cars and are forcing them to launch EV's.

So when Tesla Motors announce massive plans, the industry notices. Tesla announced plans to setup massive factories to manufacture batteries, in a move that could lower the global prices of Lithium-Ion batteries.

Tesla’s factory aims to reduce the cost of lithium-ion batteries by 30 percent in three years and 50 percent by 2020. This kind of scale they are talking about is similar to what Henry Ford did with the Model T in the 1920s. Mass manufactured cars resulted in cheaper cars that could be afordable to an average American family in the 1920s. Fast forward 90 years the same thing is happening in the EV industry - mass manufacture Lithium-ion battery packs and get the costs down and thus make affordable EVs.

The Numbers

The numbers just boggles the mind! Tesla plans to manufacture battery packs with total pack output of

50 GWh per year!

So if each Tesla car has say a 100 kWh pack (say in 2020 they use a 100 kWh pack in each Tesla car)

As 1 GWh = 1000000 kWh, if they manufacture battery packs worth - 50000000 kWh of output, that is enough battery packs for 500 thousand Tesla electric cars!!!!

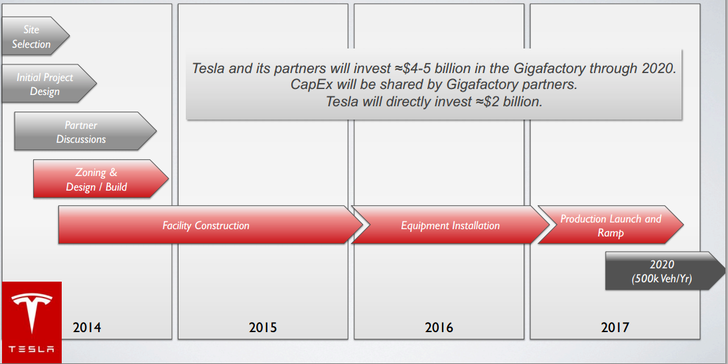

Tesla estimates it will need $4 -$5 billion to do this. They are even approaching cash rich companies like Apple to get funds (And Apple has $158 billion in cash reserves! They can surely throw a couple of billion $ to help sustainable transport?)

The numbers just boggles the mind! Tesla plans to manufacture battery packs with total pack output of

50 GWh per year!

So if each Tesla car has say a 100 kWh pack (say in 2020 they use a 100 kWh pack in each Tesla car)

As 1 GWh = 1000000 kWh, if they manufacture battery packs worth - 50000000 kWh of output, that is enough battery packs for 500 thousand Tesla electric cars!!!!

Tesla estimates it will need $4 -$5 billion to do this. They are even approaching cash rich companies like Apple to get funds (And Apple has $158 billion in cash reserves! They can surely throw a couple of billion $ to help sustainable transport?)

Tesla says,

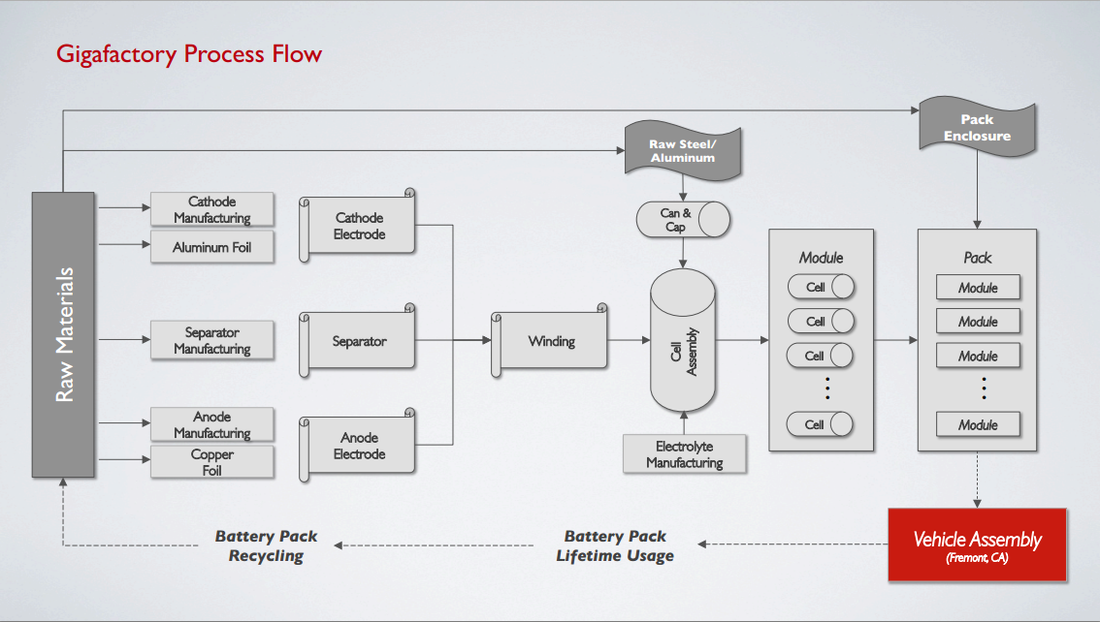

“As we at Tesla reach for our goal of producing a mass market electric car in approximately three years, we have an opportunity to leverage our projected demand for lithium ion batteries to reduce their cost faster than previously thought possible. In cooperation with strategic battery manufacturing partners, we’re planning to build a large scale factory that will allow us to achieve economies of scale and minimize costs through innovative manufacturing, reduction of logistics waste, optimization of co-located processes and reduced overhead."

“The Gigafactory is designed to reduce cell costs much faster than the status quo and, by 2020, produce more lithium ion batteries annually than were produced worldwide in 2013. By the end of the first year of volume production of our mass market vehicle, we expect the Gigafactory will have driven down the per kWh cost of our battery pack by more than 30 percent.”

American states like Arizona, Nevada, New Mexico and Texas are all in the running for the Giga factory.

“As we at Tesla reach for our goal of producing a mass market electric car in approximately three years, we have an opportunity to leverage our projected demand for lithium ion batteries to reduce their cost faster than previously thought possible. In cooperation with strategic battery manufacturing partners, we’re planning to build a large scale factory that will allow us to achieve economies of scale and minimize costs through innovative manufacturing, reduction of logistics waste, optimization of co-located processes and reduced overhead."

“The Gigafactory is designed to reduce cell costs much faster than the status quo and, by 2020, produce more lithium ion batteries annually than were produced worldwide in 2013. By the end of the first year of volume production of our mass market vehicle, we expect the Gigafactory will have driven down the per kWh cost of our battery pack by more than 30 percent.”

American states like Arizona, Nevada, New Mexico and Texas are all in the running for the Giga factory.

While Tesla’s short-term battery cost reduction will come from scale of economies, ultimately what matters is improvements in battery design and performance will provide greater value over the long term.

The EV industry should focus on research on battery technology, for example - Can a battery pack avoid degradation based on external factors, can they resist high voltage pumped in from DC quick charging stations, can they be efficient during the cold winters?

The EV industry should focus on research on battery technology, for example - Can a battery pack avoid degradation based on external factors, can they resist high voltage pumped in from DC quick charging stations, can they be efficient during the cold winters?

Tesla in India?

As per reports, Tesla Motors could make an entry into the Indian market in the near future.

Deepak Ahuja, the chief financial officer of Tesla Motors, said,

“India is a huge potential market where we need to be. “I think sometime in 2015 seems to make sense to enter India, but it’s difficult to make an official announcement.” Ahuja continued

”There is potentially a demand in India, but Tesla is a high-end luxury car so demand might be somewhat constrained initially and be similar to other luxury cars.”

So sometime in 2016 is when Tesla would finish work on their 3rd gen Model E electric car that would cost around 35,000 $. If they are serious about the Indian market, they will need to manufacture here. Sadly it wont happen in the near future.

Until then we can just hope they keep innovating and take the EV revolution to the next level.

The world is waiting!

As per reports, Tesla Motors could make an entry into the Indian market in the near future.

Deepak Ahuja, the chief financial officer of Tesla Motors, said,

“India is a huge potential market where we need to be. “I think sometime in 2015 seems to make sense to enter India, but it’s difficult to make an official announcement.” Ahuja continued

”There is potentially a demand in India, but Tesla is a high-end luxury car so demand might be somewhat constrained initially and be similar to other luxury cars.”

So sometime in 2016 is when Tesla would finish work on their 3rd gen Model E electric car that would cost around 35,000 $. If they are serious about the Indian market, they will need to manufacture here. Sadly it wont happen in the near future.

Until then we can just hope they keep innovating and take the EV revolution to the next level.

The world is waiting!