Samarth Dua gave a nice market perspective to the above question in the Quora post -

Tesla Motors: Why doesn't Tesla make small electric cars?

He made a point that Tesla wanted to build a high margin car first and sell to a niche and then use the proceeds from that to finance something even bigger (like the Model S, X and E).

I do not completely agree that Elon Musk was hoping to drive profits from one vehicle to another (Roadster never made any profit and the Model S is barely breaking even). They did however, serve as excellent marketing and validation points for Tesla.

'The window of opportunity that Tesla was trying to squeeze into (early 2000s) did not allow it.'

Allow me to explain:

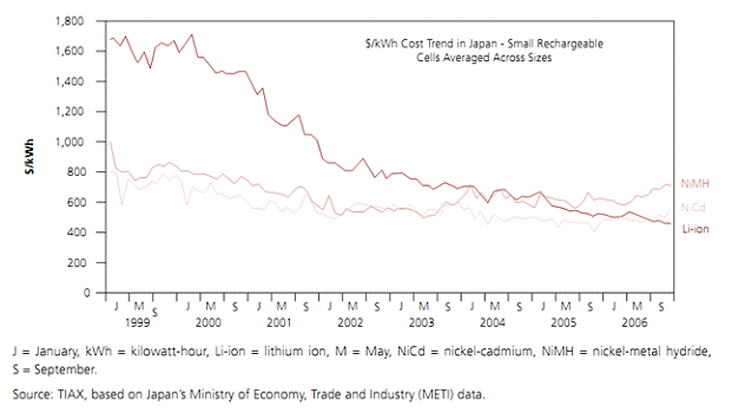

Way back in 2003, when Tesla started, lithium ion cells barely made any sense. They were prohibitively expensive for a sensible vehicle AND heavy AND bulky too. Priced at nearly $1000/kW-hr it would have costed Tesla nearly $85K just to put enough batteries for the current Model S. Add to it the fact that the batteries then weighed almost twice (probably more) than the batteries of today, using lithium ion batteries made no sense at all.

History proved them right: prices fell by a clean 8% p.a. (Battery Electric Vehicles (BEV): How fast is the price of lithium ion cells falling? (and in case of some chemistries even faster) leading to a price of nearly

$150/kw-hr for a volume importer like Tesla today. That is a massive, massive fall. That opened the door to make a commercial car.

However, it came with a rider. The fact that they wanted to use a commoditized cell sold by Panasonic, meant that their cells won't be able to give them the few thousand cycles as showcased by other OEMs. This (in my opinion) led them to an even better insight: put more cells - a lot more in fact.

Since, the pack was good for only 500 cycles or so, they could not build a pack which lasted for only 100 miles. That would not make their users very happy and lead to long-term disillusionment for them. What they needed was an immortal battery pack. There was only one way to make one: a two to three times bigger pack which would last for 200-250 miles and hence last for more than 100K miles.

This eventually meant that back in 2003 this pack would be phenomenally expensive. And since, the cost of an EV is significantly dictated by the cost of the cells it meant that the entire vehicle cost would be phenomenally expensive. From a systems perspective, it makes no sense to cut corners when the car you are building is already reaching $60-$70K+ territory. Thus you change your design criterion and pile more features on it and make it a super car (ala the Roadster).

Thus, Tesla - even if it really, really wanted to, could not build a low cost vehicle back then. The economics of the cells pretty much dictated the economics and hence the marketing strategy for their entire vehicle.

Page on powerelectronics.com

EV Myths And Realities, Part 3B: EVconomics - It's The Stupid Battery

Tesla Motors: Why doesn't Tesla make small electric cars?

Battery Electric Vehicles (BEV): How fast is the price of lithium ion cells falling?

Lithium Iron Phosphate Battery Technology

Tesla Roadster