Vijay started by underlining the importance of incentives by the government. The example he took was of Denmark, where sales plummeted since the time tax incentives have been withdrawn. (Btw, most of the EV sales in Denmark are Tesla) Battery supply is very oligopolistic. The main players are Panasonic, BYD, LG, AESC and Samsung. The top two EV cities in the world are: Shenzhen and Oslo. Zone restrictions help a lot in EV adoption. The government perspective on mobility solutions center around job creation and utilisation of existing infrastructure. We discussed the Chinese threat. Vijay felt that if the IC engine auto industry has managed to remain largely indigenous, the same will be the case for EV also. He felt that the future is going to be in shared or connected vehicles. Instead of looking at EV's as a total solution, it is better viewed as just one piece of the puzzle.

Sriram talked about the issues faced by the bus manufacturers. Unlike cars, electric buses have a very low cool quotient, primarily because they operate in a B2B setup. Buses can be differentiated on usage per day .... schools and municipal transports represent two ends of the spectrum. Apart from tech challenges, Municipal transports also have to deal with low occupancies in cities where there are share auto routes. For SRTCs, the presence of many unremunerative routes leads to losses and thereby ticket pricing constraints. In this scenario, the challenge for SRTC is in tendering for new technology. What architecture should they go for? Will it be safe for passengers? Will there be longevity in the OEM’s global supply chain? 400 kwh batteries weigh a lot. Should I transport batteries or passengers?

From a supply chain perspective, the volumes are unclear. Clients who want to be technology agnostic are asking OEMs to take the risk and become the pilot operators. Probably we are moving towards mobility as a service. Sriram thinks that SRTC focus should be only on specs, uptime and passengers safety. Whether the buses are hydrogen fuelled or electric, is a call that OEMs can take.

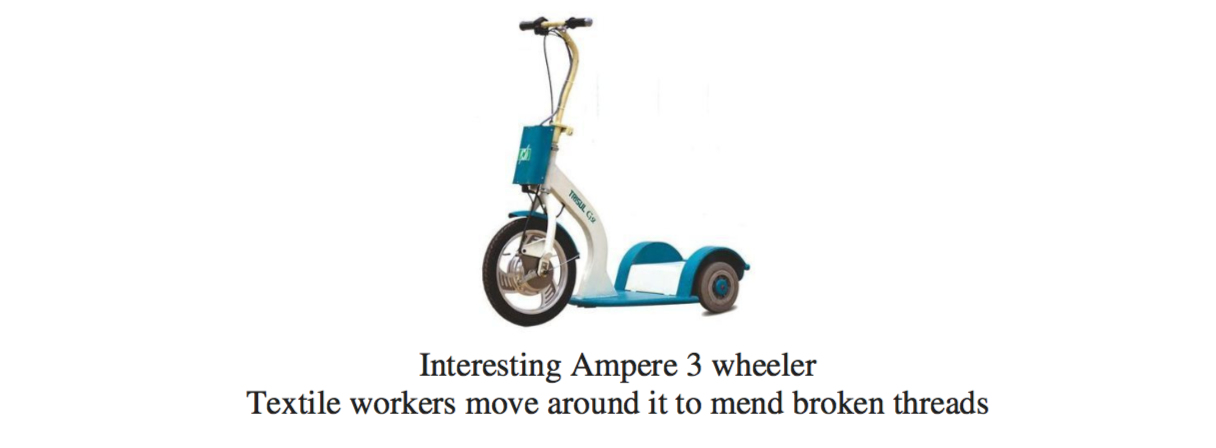

Hemlata was earlier working with Wipro. She started Ampere Motors in Coimbatore about 10 years ago. Interestingly, about 30% of the company workforce is women. I asked her what is the volume at which an EV manufacturer breaks even. She thought the figure would be about 3000 per month. Ampere Motors has sold almost 35,000 vehicles so far. According to Hemlata, adoption of electric vehicles has been very low amongst the educated upper classes. The typical two wheeler EV customer is the lower middle class common man. Typical customers are small farmers and bank employees, who are ok with the constraint of range. Hemlata feels that the market would continue to be good for electric vehicles in Tier 2 cities. She believes that the metro users are the ones who want instant gratification. Unless two wheeler range goes up to 120 - 200 km, they will not buy. Once in the market, she met a customer who told her (in Tamil), ‘Give me a cycle which looks like a cycle.’ Hemlata has taken this too heart and decided that most of Ampere’s innovation has to be in the internals, rather than externals. Ampere Motors also makes its own chargers. Hemlata claims that she has not seen any cases of battery bulging in her vehicles because of the charger quality. Ampere makes its own power train. They have a very value for money Lithium ion model which is priced at 40 K. I had a test drive and I was quite happy with the acceleration.

In China, there are 42 million electric vehicles on the roads today. 96 percent are using lead acid batteries. The two big problems associated with Lithium ion batteries are cost and safety. In China the temperatures are much lower, so Lithium ion batteries run safer. For India to develop, we need a plant which will make lithium cells. This will require an investment of about 1 to 2 billion dollars. She feels that before we Make in India, we will have to Mine in India. The current battery cost is to $73 for 1 kWh. She feels that unless costs come down to less than $100 per kWh, the country will not be able to meet its target of switching over to electric by 2030. One of the audience questions put to her was a popular conception about the performance of EVs in rains. Another thing that worries rural customers is power outages. Hemlata believes that subsidy cannot be a solution for the EV industry. She was representing the Society of Manufacturers of Electric Vehicles. Today there are only about 8 two wheeler EV manufacturers and about 3 three wheeler manufacturers. In 2008 there used to be 68 two wheeler manufacturers. She was very emphatic that the electric vehicle is going to be more about two wheelers than cars. Government policy is going to be driven mostly towards the adoption of EV two wheelers. Hemlata felt that the government should have a specific policy for EV promotion. One example she gave us to have only EV days on city roads.

http://www.amperevehicles.com/

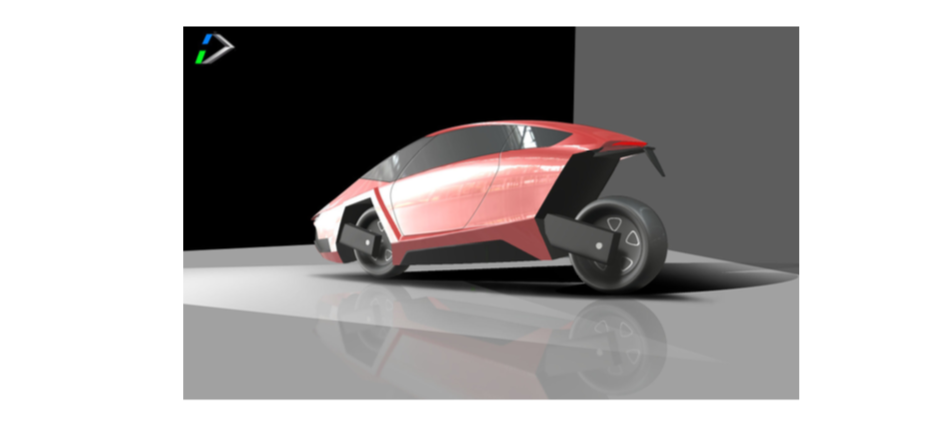

Jacob’s company works in the IIT Madras incubation center. Their work is on pedal assisted 3 wheelers. A very interesting opinion that Jacob had was a new definition of luxury. Luxury, he says, now is clean air and water. Them delving into his M.Tech knowledge of IC engines, he says that earlier it was assumed that the higher the temperature you work on the more efficient the engine is. But the Carnot equation also has a temperature for the Low temperature heat reservoir – in other words atmospheric temperature. We cannot assume Tc to be constant any more. It is going up – primarily because of our automotive engines. One of the issues that bother Jacob is the kerb weight to payload ratios – which basically means how much of deadweight are you lugging around to carry the 65 kg passenger. A typical car runs with a ratio of 3.5 The best ratio is for cycles - 0.23. So his solution is more about empowering the humble power plant that is the human being.

Here is a link to an article in Hindu on their company:

http://www.thehindubusinessline.com/specials/emerging-entrepreneurs/pi-beam-labs-makes-ecofriendly-tricycles/article9395147.ece

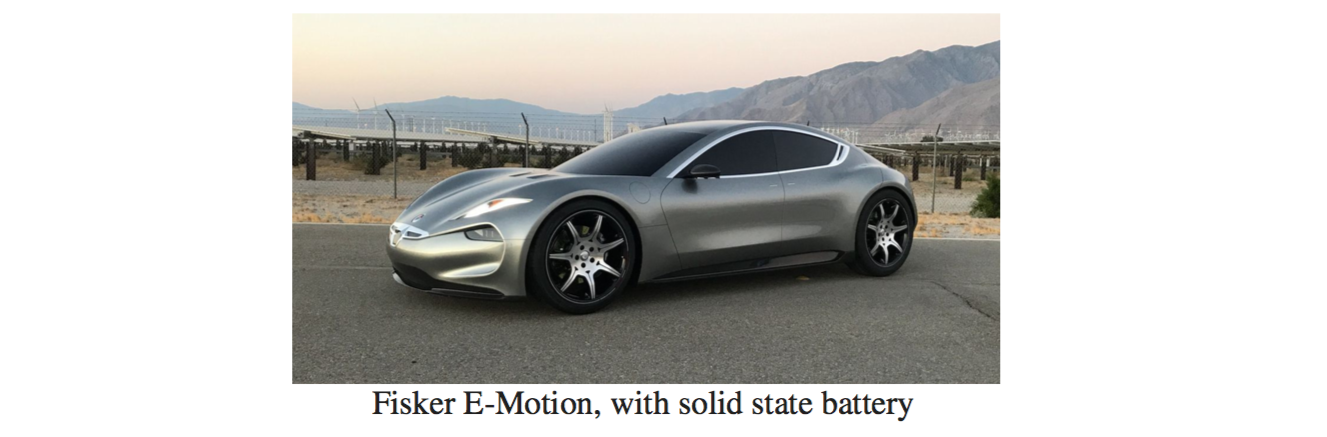

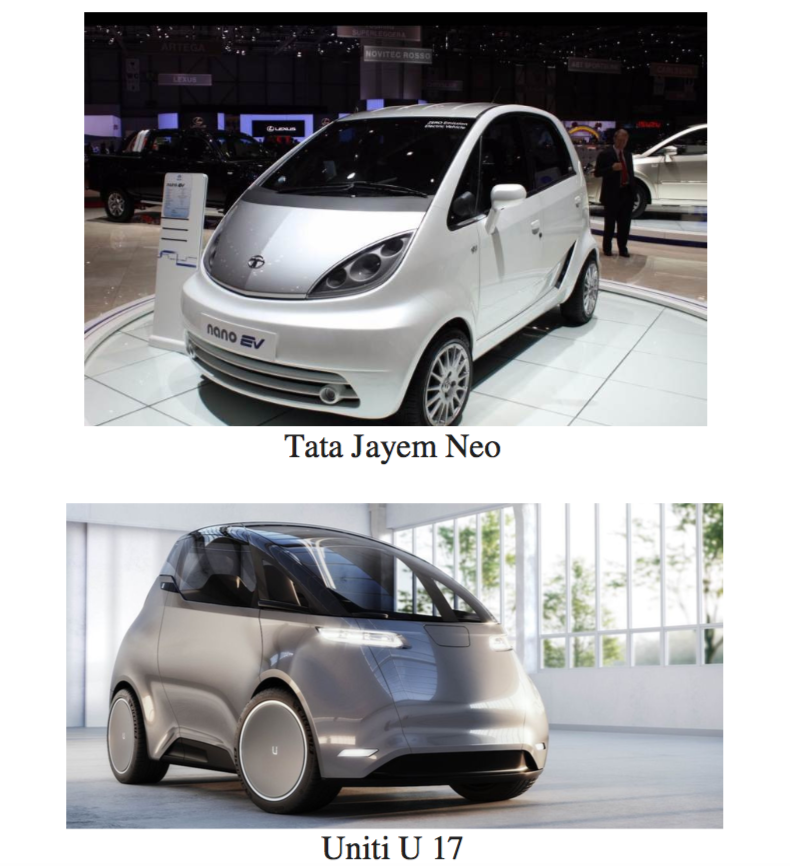

CAS modelling is a Pune based company headed by Yogesh Iyer. It counts amongst its clients the niche EV manufacturer, Fisker Motors - www.fiskerinc.com Fisker is an EV super car manufacturer, which has been funded partly by Bob Lutz. Yogesh talked of the electric car

models which showed promise. I'm listing down some of the ones I thought look interesting:

http://casmodeling.in/

Lohia Auto is a 10 year old company, which is into the manufacturing of e rickshaws. The Managing Director, Ayush Lohia, had come for the talk. The e-rickshaw revolution started in 2011, mostly in Delhi and Haryana. Earlier there was very little regulation, but from July 2015 onwards e-rickshaws are registered under the Motor Vehicles Act. As with the electric scooter industry, there are a lot of fly by night operators, who don't give spare and service support. Motors and controllers for e-Rickshaws are still largely being imported.

www.lohiaauto.com

Gaayam Motor Works is a company involved in the manufacture of electric cycles and 3 wheelers. Raja talked about sodium iron and Zinc air battery, which will have much higher energy density and will start entering the market 10 years from now. Interestingly lithium carbonate is available plentifully in India.

Another interesting company is FT Motors Private Limited, also known as Sina mobility. They are working on a self balancing two wheeler. This uses a gyroscope for balancing.

http://www.sinamobility.com/

Dr R Gopalan is a powder metallurgy specialist, who has worked with Toyota in the magnet development program for hybrid cars in Japan. One of the interesting statistics he presented was that in 2008 there were only 2000 electric cars sold worldwide. In 2016 the number has already crossed 7 lacs. India has 148,000 electric vehicles on the roads. He has predicted a sharp decrease in car prices. By 2035 he expects EV car prices is to drop to less than $10,000 in the United States.

Most of his talk was devoted to battery pricing. The major cost in a battery today comes from the cathode - about 36%. Next is the anode at 13% and following that you have the separator, the electrolyte, the copper foil, the aluminium foil and graphite. Lithium ion cells have an output of 3.6 volts versus 1.2 V for lead acid, which is one of the reasons for the compactness. Dr Gopalan’s lab aims to make a battery which can give a car a range of 500 km with a battery weight of just 200 kilograms. ISRO and IIT Madras are the only two Institutions which have capability to make Lithium ion batteries from scratch. The basic raw material is LiFePO4. This goes through a carbonation process for electron transfer to happen.

Another area that the professor touched upon for EV materials is the motor magnets. NdFeB magnets can withstand high temperature inside the motor. More than 200 degree Celsius. High temperature is the biggest cause of motor failure. The lab is also working on a replacement for Silicon Steel used in motor cores.

IIT Madras also has a program in supercapacitors. Another interesting research area is the perovskite solar cell. A perovskite solar cell is a type of solar cell which includes a perovskite structured compound, most commonly a hybrid organic-inorganic lead material, as the light- harvesting active layer. Perovskite materials are cheap to produce and simple to manufacture.

Devi is the Director of IESA, an alliance of 80 battery manufacturers. Most of his session was devoted to statistics. Here are the interesting ones:

• 60 percent of EV cost is battery

• 6 GWh of battery manufacturing capacity is in the US. China is 8 GWh.

• Major markets for EVs in India will be 3, 2 wheelers

• Material handling will be quite a big market for EVs

• There are 9 chemistries in Li ion batteries. Lithium iron phosphate is one of the popular types.

• The current battery storage cost is 270 $ per kWh. It is expected to drop to 182 $ per kWh by 2025.

• There are about 20 assemblers of Li-ion batteries in India.

• Elon Musk’s factory is called a giga factory because it can produce 1 GWh of batteries in a year.

• One issue facing batteries is thermal runaway. This occurs in situations where an increase in temperature changes the conditions in a way that causes a further increase in temperature, often leading to a destructive result.

• Reliance has plans of putting up a lithium batteries plant.

Ola and Uber will help drive EV more than the government. The government should focus more on infrastructure and regulation. Lack of right regulations has hit the telecom industry badly. We do not want the GSM CDMA Telecom battles being repeated in the EV Industry. Another area it can help is to create a manufacturing ecosystem. Hemlata felt that in order to decrease the upfront cost of electric vehicles, GST should be zero. For the second battery the GST cannot be the astronomical 28% that it is currently; it should be a maximum of 5%. Next on Hemlata’s wishlist was a mandate to all Nationalised banks to give loans for electric vehicles. Government should set up a Lithium manufacturing plant. The electric vehicle industry should stop making chalta hai products and instead focus on good quality. In any case, China is trying to change its image from a volume producer to a value one. Almost all the speakers talked off the troubles the photovoltaic panel faced because of China. The insight was that the problem’s genesis was in government policy, which was skewed towards assemblers rather than manufacturers. With the right government policy India has managed to protect its auto industry. Even when the auto industry is down, companies like Kia Motors are looking at making billion-dollar investments in India.

Hemlata felt that entrepreneurs in the EV space could benefit from opportunities in battery leasing. Another was to become intermediaries for EV vehicle selling in the B2B market. Mr Purohit of Axiom Energy, a leading maker of battery chargers, felt that entrepreneurs should focus on a smaller area and become the leaders in that area. One interesting suggestion from the audience was to launch electric vehicle maintenance course in schools.

- The e2o 4 door has got Electrical power steering. The battery voltage is 48 volts and the fast charger draws 240 ampere of current.

- Dravak Technologies is company incubated in IIT Madras and they are looking out for making fast charging stations.

- Hero Electric is making about 2500 bikes a month.

- Nitto is a Japanese company which is tape supplier for heat transfer and water sealing. They are supplying To Tesla, Nissan and BYD.

- Prashant is a Dapoli based entrepreneur who is into solar solutions. Interestingly they have an automated solar based dust removal system for their solar panels. One of the ideas I have had was to create a Green Island near the place where the panel is fitted, so that the dust problem is reduced.

- Met with Mr Bishnoi of L&T, who is working with grids and switchgears. One of the interesting products is a safety one, related to prevention of arcing in switchgear.